Table of Contents

Introduction

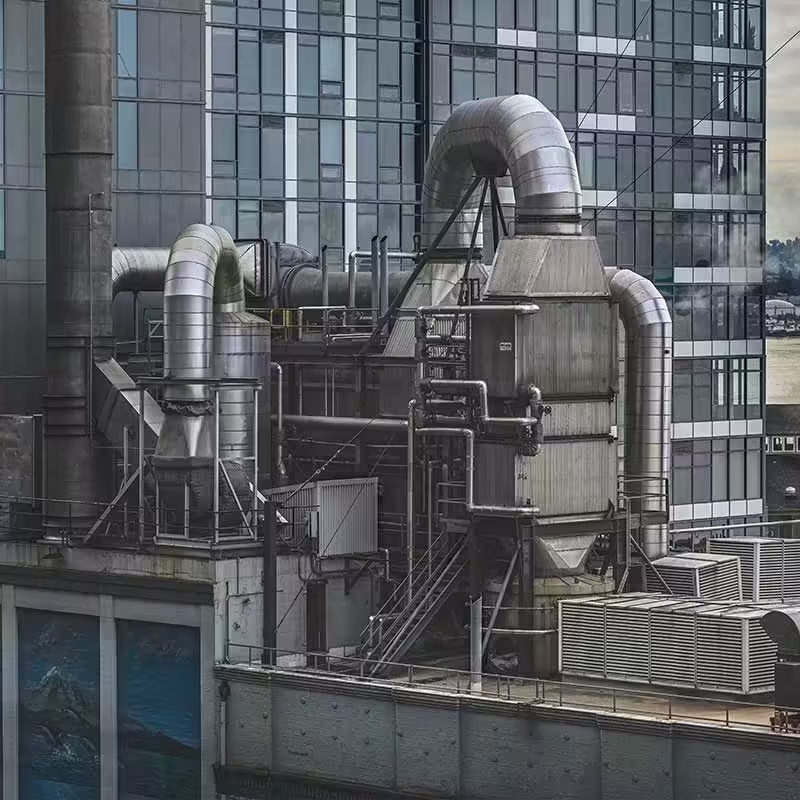

The industrial incinerator has become a cornerstone of modern waste management, serving as a high-temperature combustion system capable of addressing hazardous and complex waste streams. Its role goes far beyond simple disposal; it encompasses safety, environmental compliance, energy recovery, and operational efficiency. By converting harmful waste into stable byproducts such as carbon dioxide, water vapor, and inert ash, the system protects both industry workers and the environment.

This blog provides 10 critical insights into how an industrial incinerator works, the key performance metrics that define its success, and the practical considerations for industries that rely on it. Understanding these insights allows manufacturers, engineers, and facility operators to maximize efficiency while maintaining compliance with stringent emission standards.

Insight 1: The Role of Thermal Oxidation in Industrial Incinerator Design

Thermal oxidation remains the cornerstone of every high-capacity waste treatment system. When industrial byproducts, often comprising solvents, contaminated packaging, or sludge, are fed into the primary combustion chamber, temperatures ranging from 800°C to 1200°C or higher ensure complete chemical breakdown. This process transforms hazardous hydrocarbons and volatile organic compounds into carbon dioxide, water vapor, and inert ash.

The performance of such equipment is governed by three essential combustion parameters:

- Temperature: Sufficiently high to initiate and sustain the oxidation of organic matter.

- Residence Time: Ensuring waste materials remain in the chamber long enough for complete decomposition.

- Air Supply: Providing the exact stoichiometric oxygen to avoid incomplete combustion or excess emissions.

When these factors are balanced, the system can achieve destruction removal efficiencies exceeding 99.9%. This ensures that even persistent organic pollutants and hazardous chemicals are neutralized before release, protecting public health and the environment.

Insight 2: Volume Reduction and Waste Minimization

A major advantage of the industrial incinerator is its capacity to dramatically reduce waste A major advantage of thermal treatment units is their capacity to dramatically reduce waste volume. In some cases, solid residues are diminished by up to 90%. This reduction is particularly critical for industries generating high volumes of hazardous byproducts, such as chemical processing plants or pharmaceutical manufacturers.

Benefits include:

- Lower landfill costs due to smaller waste mass.

- Simplified storage requirements for residual ash.

- Reduced transportation needs, minimizing the risk of hazardous material spills during transit.

For companies bound by strict environmental compliance, onsite incineration significantly reduces logistical complexity and enhances overall safety. By compressing large volumes of hazardous waste into a fraction of their original size, the technology also supports circular economy models by freeing up storage space and reducing landfill reliance.

Insight 3: Industrial Incinerator Energy Recovery Potential

One of the most forward-looking features of an industrial incinerator is its ability to transform waste into usable energy. The combustion process releases substantial amounts of heat, which can be captured through heat exchangers, boilers, or cogeneration systems.

Common applications of recovered energy include:

- Generating steam to drive turbines for electricity.

- Supplying heat to other industrial processes, such as chemical reactors or drying units.

- Integrating with district heating systems to support local communities.

By reclassifying waste as a potential energy source, industries benefit from cost savings while simultaneously lowering their dependence on fossil fuels. This dual-purpose approach strengthens the financial case for industrial incinerator adoption and contributes to broader decarbonization strategies.

Insight 4: Industrial Incinerator Emission Control Mechanisms

Even though thermal oxidation is highly effective, emissions control is essential to ensure compliance with modern environmental standards. The gases released—often containing trace nitrogen oxides, sulfur compounds, and particulates—must be treated before being discharged into the atmosphere.

Typical control systems include:

- Wet or dry scrubbers: Remove acidic gases such as SOx and HCl.

- Electrostatic precipitators or fabric filters: Capture fine particulates and heavy metals.

- Selective catalytic reduction (SCR): Reduces NOx levels to meet stringent limits.

By combining these systems, industries achieve near-zero harmful emissions, making this technology a sustainable waste management tool.

Insight 5: Industrial Incinerator Applications Across Industries

The versatility of the industrial incinerator is evident in its wide range of applications. From chemical factories to e-waste recyclers, industries utilize these systems to handle specialized waste streams.

Here is a detailed table summarizing functions and applications:

| Function | Description | Example Industry Use Case |

|---|---|---|

| Thermal Oxidation | Converts organic matter into CO₂, H₂O, and stable gases | Chemical manufacturing |

| Hazardous Waste Treatment | Breaks down toxic substances to prevent contamination | Pharmaceutical and biomedical |

| Energy Conversion | Transforms chemical energy into usable heat | Petrochemical and refining |

| Emission Control | Minimizes pollutant release through filtration and scrubbing | Electronics recycling |

| Volume Reduction | Shrinks waste by up to 90% for easier disposal | Paint and coating industries |

This table highlights the diverse functions that contribute to the high performance of an industrial incinerator.

Insight 6: Environmental Compliance and Global Standards

In today’s industrial landscape, performance cannot be judged solely by technical efficiency. Regulatory compliance is equally important. These systems are designed to meet or exceed strict standards established by agencies such as the EPA, the European Union, and the World Health Organization.

To achieve compliance, many are equipped with:

- Continuous emission monitoring systems (CEMS).

- Automated reporting functions for regulatory submission.

- Integrated gas purification modules.

Failure to comply can result in severe financial penalties, reputational harm, or even operational shutdowns. As a result, advanced incinerators are increasingly viewed not just as disposal tools, but as compliance enablers.

Insight 7: Industrial Incinerator Maintenance and Reliability

Performance is closely tied to maintenance. Even the most advanced incinerator requires Like Like any sophisticated equipment, performance is strongly tied to maintenance practices. Even the most advanced models require consistent care to operate at peak levels.

Typical maintenance procedures include:

- Inspecting burners and air injectors for wear.

- Cleaning accumulated ash and clinker from combustion chambers.

- Replacing filters and catalytic elements in emission systems.

- Verifying automated control systems.

Without regular upkeep, operators risk efficiency losses, excess emissions, or even catastrophic equipment failure. Many facilities now implement predictive maintenance strategies—using IoT sensors and data analytics—to anticipate issues before they escalate.

Insight 8: Advanced Automation in Industrial Incinerator Systems

Modern waste treatment plants are highly automated, digitally integrated systems. Automation helps ensure optimal combustion conditions are maintained 24/7, with minimal human intervention.

Key features include:

- Real-time temperature monitoring.

- Automated waste feed adjustment based on calorific value.

- Safety shutdowns triggered by anomalies.

- Remote digital dashboards for operators.

These features not only improve energy efficiency but also reduce the risks associated with human error.

Insight 9: Safety Considerations in Industrial Incinerator Operation

Safety is paramount when dealing with hazardous waste and high temperatures. Industrial Operating an industrial incinerator involves handling hazardous waste and managing extreme temperatures, making safety a top priority. Systems are therefore designed with multi-layered safety protocols.

Key safety measures include:

- Emergency shutdown systems to halt operations in critical situations.

- Pressure relief valves to prevent overpressurization.

- Sealed waste feed chambers to protect operators from exposure.

- Remote monitoring systems that allow supervisors to manage processes offsite.

Adhering to strict operational guidelines not only protects the workforce but also prevents accidents that could cause environmental damage or financial liability.

Insight 10: The Future of Industrial Incinerator Technology

The role of high-capacity incineration is evolving rapidly as industries seek more sustainable, efficient, and technologically advanced solutions. Future developments are expected to focus on:

- Improved waste-to-energy conversion systems.

- Integration with renewable power sources such as solar or biomass.

- Use of AI-driven predictive models to optimize performance.

- Enhanced carbon capture integration for climate-neutral operations.

As waste streams become more complex and environmental expectations rise, this technology will remain a cornerstone of advanced waste management strategies worldwide. Its future lies not just in disposal, but in turning waste into value while aligning with global sustainability goals.

Conclusion

The industrial incinerator is more than a disposal device; it is a strategic system that addresses waste management, energy efficiency, environmental compliance, and safety. By understanding the 10 critical insights outlined in this blog, industries can make informed decisions about design, operation, and maintenance.

From volume reduction to energy recovery and from emission control to future-ready automation, the performance of an industrial incinerator defines the efficiency and responsibility of modern industrial waste management practices.

FAQ

Q1: What types of waste can an industrial incinerator handle?

It can treat hazardous, chemical, pharmaceutical, petrochemical, and biomedical waste, as well as non-recyclable components of e-waste.

Q2: What is the typical operating temperature of an industrial incinerator?

Most operate between 800°C and 1200°C, though some designs exceed these temperatures for specific waste streams.

Q3: How much can an industrial incinerator reduce waste volume?

It can reduce solid waste volume by up to 90%, significantly lowering disposal requirements.

Q4: Is energy recovery possible with industrial incinerators?

Yes, the heat generated can be reused for steam generation, electricity, or process heating.

Q5: What industries benefit most from industrial incinerators?

Chemical plants, pharmaceutical manufacturers, petrochemical facilities, electronics recyclers, and paint industries benefit significantly.

Q6: How are emissions controlled in an industrial incinerator?

Advanced scrubbers, filters, and catalytic systems minimize pollutants and ensure regulatory compliance.

Q7: Does an industrial incinerator require regular maintenance?

Yes, consistent inspection and cleaning are essential to ensure safe, efficient, and reliable operation.

Q8: How safe are industrial incinerators to operate?

They are equipped with automated controls, safety valves, and monitoring systems that make them safe when operated correctly.

Q9: Can industrial incinerators contribute to sustainability?

Yes, by reducing landfill reliance, recovering energy, and minimizing environmental risks, they support sustainability goals.

Q10: What future trends are shaping industrial incinerator performance?

Greater automation, digital monitoring, and integration with renewable energy systems will define future developments.