Table of Contents

Introduction

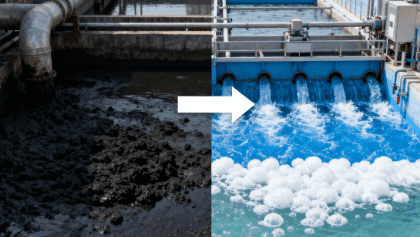

Water is an indispensable resource, yet its quality is constantly threatened by industrial activities, urban development, and a myriad of pollutants. From suspended solids and oils to complex chemical compounds, the challenges in wastewater treatment are profound and ever-evolving. Enterprises, municipalities, and communities globally face the urgent task of ensuring cleaner effluent, protecting natural ecosystems, and meeting increasingly stringent discharge standards. The pursuit of sustainable and eco-friendly production methods hinges significantly on effective wastewater management.

In this landscape of critical environmental concerns, innovative solutions are not just desirable but essential. One such breakthrough is the air flotation device, a technology that has revolutionized the way we approach solid-liquid and liquid-liquid separation in wastewater treatment. This blog post will delve into the core principles, multifaceted functions, and diverse applications of air flotation equipment, highlighting how it serves as a cornerstone of modern wastewater treatment systems. We will explore its significant advantages and demonstrate its capability to address some of the most pressing water treatment crises faced today, ensuring environmentally responsible and economically sound operations.

Understanding the Water Treatment Crisis

The modern world grapples with several critical water treatment crises, each posing a unique threat to public health and environmental integrity. Industrial sectors, ranging from food processing to petrochemicals, generate vast amounts of wastewater laden with fats, oils, suspended solids, dyes, heavy metals, and hydrocarbons. Municipalities deal with high-load industrial or commercial waste inflows that strain biological treatment units. Hospitals contend with pathogens, organic matter, and heavy metals in their effluent. These pollutants, if untreated, can lead to severe environmental degradation, contaminate water sources, and pose significant health risks.

The removal of fine particles, emulsified oils, and colloidal substances often proves challenging for conventional treatment methods. Moreover, the increasing demand for water reuse and stricter regulatory compliance necessitates highly efficient and reliable purification technologies. Traditional approaches can be energy-intensive, require substantial chemical consumption, and may result in large volumes of sludge, adding to operational burdens. The need for compact, energy-saving, and automated solutions that can reduce the load on secondary treatment systems while improving overall water quality is paramount. These multifaceted challenges underscore the urgent requirement for advanced solutions like the air flotation device, capable of providing rapid, efficient, and cost-effective pollutant removal.

What is an Air Flotation Device?

An air flotation device, often referred to as an air flotation unit or machine, is an advanced solution for efficient wastewater purification. At its core, this equipment is designed to remove suspended solids, oils, and other pollutants from wastewater using microbubble flotation technology. The fundamental principle involves the introduction of pressurized air into water, which then dissolves. When this dissolved air is subsequently released under reduced pressure in a flotation tank, it generates microscopic air bubbles, typically at the micrometer (μm) level, specifically ranging from 30-50 μm in diameter.

These tiny air bubbles act as carriers, attaching themselves to suspended particles, colloids, and oils within the wastewater. Upon attachment, they form what are known as air-floating bodies, which have a lower specific gravity than water. The buoyancy generated by these attached microbubbles lifts the pollutant-laden air-floating bodies to the water surface, forming a layer of scum or float. This surface layer is then efficiently collected and removed by mechanical scrapers, effectively separating the impurities from the water. This process ensures a highly efficient separation of solids and oils, resulting in cleaner effluent and contributing to more sustainable water treatment operations.

Key Functions of Air Flotation Units

Air flotation units perform several critical functions that collectively ensure highly effective wastewater treatment:

• Microbubble Generation: The process begins with pressurized air dissolving in water, which then produces fine bubbles upon release into the flotation tank. This is a crucial step as the size and distribution of these microbubbles directly impact the efficiency of pollutant attachment.

• Pollutant Adsorption: Once generated, these tiny air bubbles adhere to various contaminants, including suspended particles, colloids, and emulsified oils. This adsorption is facilitated by the chemical properties of the bubble surfaces and the pollutants.

• Buoyant Separation: As bubbles attach to contaminants, they form air-flotation bodies with a lower specific gravity than water. This difference in density causes them to rapidly rise to the surface.

• Scum Removal: The accumulated layer of float or scum on the water surface, consisting of the pollutants and air bubbles, is then mechanically scraped away into a collection tank.

• High-Efficiency Clarification: The overall result of these coordinated functions is a rapid and effective separation of pollutants, leading to significant clarification of the treated water.

Advantages of Air Flotation Technology

The widespread adoption of air flotation technology stems from its numerous advantages in wastewater treatment:

• Efficient Removal: It excels at the efficient removal of fine particles and emulsified oils, which are often difficult to separate using traditional sedimentation methods.

• Reduced Load on Secondary Treatment: By effectively removing a significant portion of pollutants, air flotation equipment reduces the organic and suspended solids load on downstream biological treatment systems, enhancing their performance and reducing operational costs.

• Low Chemical Consumption: Compared to some other treatment methods, air flotation units can achieve high clarification performance with relatively low chemical consumption, leading to cost savings and reduced chemical sludge.

• Compact Structure and Footprint: These units typically have a compact structure, requiring a smaller installation footprint, making them suitable for facilities with limited space.

• Energy-Saving Operation: Modern air flotation devices are designed for energy-saving operation, often incorporating automated control options that optimize performance and minimize energy use.

• Improved Sludge Dewaterability and Reduced Sludge Volume: The nature of the float generated by air flotation often leads to sludge with better dewaterability, and the overall volume of sludge produced can be reduced, simplifying sludge handling and disposal.

• Odor and Surfactant Removal: The aeration process inherent in air flotation also contributes to the removal of surface active agents and odors from the water, improving overall water quality.

• Enhanced Dissolved Oxygen: The introduction of air increases dissolved oxygen in the water, which can provide favorable conditions for subsequent aerobic biological treatment steps.

• Versatility: It performs particularly well with challenging water sources, such as those that are low-temperature, low-turbidity, or contain high concentrations of algae.

Where Air Flotation Devices Excel: Application Scenarios

Air flotation units are versatile and widely utilized across various industrial and municipal sectors that require reliable separation of oils, solids, or colloidal particles from wastewater.

| Application Sector | Primary Pollutants Removed | Key Benefits of Air Flotation Equipment |

| Food Processing Industry | Fats, oils, suspended solids, organic matter | Treats effluent from meat packing, dairy, and seafood processing, protecting biological treatment. |

| Petrochemical & Refining | Hydrocarbons, oily substances | Separates oils from process water, safeguarding downstream systems and improving water reuse. |

| Textile & Dyeing Plants | Dyes, sizing agents, suspended particles | Meets stringent discharge requirements by removing color and suspended matter. |

| Paper & Pulp Mills | Whitewater, fiber residues | Treats whitewater, enhancing clarity and significantly reducing sludge volume. |

| Municipal Wastewater Pretreatment | High-load industrial/commercial waste inflows | Reduces the burden on municipal biological units, ensuring efficient overall treatment. |

| Tannery & Leather Manufacturing | Emulsified oils, chromium compounds, fine solids | Enables regulatory compliance and water recycling by capturing challenging pollutants. |

| Chemical Industry | Various suspended solids, oils, and complex colloids | Crucial for pre-treatment and internal process water purification. |

| Electroplating | Heavy metals, suspended solids | Helps in the removal of contaminants, contributing to compliance and resource recovery. |

| Pharmaceutical Industry | Organic compounds, suspended particles | Ensures high-quality treated water for discharge or reuse. |

| Steel Industry | Oils, suspended solids, heavy metals | Addresses specific challenges in steel production wastewater. |

The Air Flotation Process in Detail

The operation of an air flotation device follows a well-defined process to achieve efficient pollutant separation:

1. Chemical Pre-treatment

Raw wastewater first enters a mixing reactor. Here, chemical substances such as degreasing agents or coagulants are added. These chemicals facilitate the aggregation of smaller pollutants into larger, more easily separable flocculates. High-efficiency tubular dosing reactors (PFRs) are often used for this stage, designed with multiple mixing tubes to control energy and time for optimal flocculation and minimal chemical consumption.

2. Microbubble Introduction and Adhesion

The pre-treated wastewater then flows into the air flotation unit. Simultaneously, air-dissolved water, pressurized to create fine microbubbles (typically 30-50 μm in diameter), is released into the incoming wastewater stream. These microscopic bubbles efficiently mix with the wastewater and attach themselves to the flocculated pollutants. This attachment forms composite air-floating bodies that have a lower specific gravity than the surrounding water.

3. Buoyant Rise and Scum Formation

Driven by buoyancy, these air-floating bodies rapidly ascend to the water surface. As they accumulate, they form a dense layer of scum or floating oil.

4. Scum and Sludge Removal

A mechanical scraper continuously moves across the water surface, collecting this scum layer and transferring it into a dedicated collection tank. Concurrently, any heavy solid particles that do not float will settle at the bottom of the inlet chamber. These settled solids are then periodically discharged via a sand discharge valve to keep the chamber clean.

5. Enhanced Separation with Inclined Plates

As the wastewater continues through the air flotation unit into a water distribution area, rapidly rising particles quickly float. Slower-rising particles can be effectively separated using corrugated inclined plates or tubes. Once a particle contacts these inclined surfaces, it can, under the influence of buoyancy, ascend against the water flow direction, further enhancing separation efficiency.

6. Bottom Sludge Collection and Discharge

All remaining heavy particles that fail to float will eventually settle to the bottom of the tank. A bottom scraper collects these settled particles, which are then discharged through a mud discharge valve that is opened periodically. This comprehensive multi-stage process ensures maximal pollutant removal and efficient clarification of the wastewater.

Addressing Water Treatment Challenges with Air Flotation

The “9 major water treatment crises” can be effectively mitigated, and often resolved, through the strategic implementation of air flotation equipment. These crises typically involve the presence of suspended solids, oils, and other complex pollutants that resist conventional treatment methods.

Crisis 1: High Suspended Solids Load

Many industrial wastewaters, like those from paper and pulp mills or food processing, carry a heavy load of suspended solids. Air flotation units efficiently remove these fine particles and fiber residues, significantly reducing the load on subsequent treatment stages.

Crisis 2: Emulsified Oils and Greases

Petrochemical, refining, and food processing industries often deal with emulsified oils and fats that are difficult to separate. Air flotation technology excels at breaking these emulsions and lifting the oily substances to the surface for removal.

Crisis 3: Challenging Colloidal Particles

Colloidal particles, often found in textile dyeing or tannery wastewater, are too small to settle by gravity. The microbubbles of an air flotation device effectively attach to and float these colloids, enabling their removal.

Crisis 4: High Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD)

By removing a substantial portion of organic matter, oils, and suspended solids, air flotation significantly reduces the COD and BOD of wastewater, making it easier for biological treatment systems to meet discharge limits.

Crisis 5: Inefficient Sludge Management

Traditional treatment can produce large volumes of wet sludge that is difficult to dewater. Air flotation improves sludge dewaterability and reduces its overall volume, simplifying disposal and lowering costs.

Crisis 6: Large Footprint Requirements

Facilities with limited space often struggle with bulky wastewater treatment equipment. The compact structure of air flotation units offers a significant advantage, requiring a smaller footprint for installation.

Crisis 7: High Energy and Chemical Consumption

The optimized design and automated control options of modern air flotation equipment contribute to energy-saving operations and low chemical consumption, addressing the economic and environmental concerns associated with high resource use.

Crisis 8: Difficult-to-Treat Water Sources

Low-temperature, low-turbidity, or algae-rich water sources pose unique challenges. Air flotation has proven effective in treating these difficult wastewaters, achieving good clarification results.

Crisis 9: Stringent Discharge Standards and Water Reuse Demands

Meeting increasingly strict environmental regulations and enabling water reuse requires highly effective purification. Air flotation units provide high-efficiency clarification, bringing wastewater closer to compliance or making it suitable for recycling, promoting sustainable and eco-friendly production.

Through its superior bubble generation and flotation mechanisms, the air flotation device ensures that wastewater management is both environmentally responsible and economically sound, offering breakthrough solutions to these persistent water treatment crises.

Lushun‘s Role in Air Flotation Solutions

Shandong Lushun Environmental Technology Co.Ltd. is an environmental protection professional technology enterprise that integrates environmental protection technology innovation, environmental protection equipment manufacturing, integrated supply of environmental protection products, and related technical services. The company offers full-process waste and wastewater treatment equipment solutions, which include flotation equipment. They focus on high-tech environmental protection products, emphasizing wastewater treatment solutions that are designed for high efficiency and energy savings. Their commitment to innovation helps customers achieve a win-win in environmental protection and economic benefits, promoting sustainable development.

Conclusion

The pervasive challenges of wastewater treatment—from the removal of complex industrial pollutants to the demands of sustainable water reuse—underscore the critical need for advanced and efficient solutions. The air flotation device stands out as a powerful and indispensable technology in this arena, offering a breakthrough approach to solid-liquid and liquid-liquid separation. Its core mechanism, leveraging microscopic air bubbles to selectively lift and remove pollutants, provides an elegant and highly effective method for purifying a diverse range of wastewaters.

From the food processing industry to petrochemical refining, and from textile dyeing plants to municipal pretreatment facilities, the versatility and robust performance of air flotation equipment are evident across numerous application scenarios. Its key advantages, including high efficiency in removing fine particles and emulsified oils, reduced load on secondary treatment systems, low chemical consumption, and a compact footprint, make it an economically sound and environmentally responsible choice.

By addressing critical issues such as high suspended solids, difficult-to-treat colloids, and the need for improved sludge management, air flotation units are not merely purification devices; they are cornerstones of modern wastewater treatment systems. Embracing this technology is a vital step toward achieving cleaner water, meeting stringent environmental regulations, and fostering sustainable practices for a healthier planet.

FAQ

Q1: What exactly is an air flotation device and how does it work?

An air flotation device is wastewater treatment equipment designed to remove suspended solids, oils, and other pollutants. It works by dissolving pressurized air into water, which then releases microscopic bubbles (30-50 μm) when pressure is reduced. These bubbles attach to contaminants, forming buoyant air-floating bodies that rise to the surface as scum, which is then removed by a scraper.

Q2: What types of pollutants can an air flotation unit effectively remove?

An air flotation unit is highly effective at removing a wide range of pollutants, including suspended solids, fine particles, emulsified oils, greases, colloids, dyes, sizing agents, fiber residues, and even certain chromium compounds. It significantly reduces the chemical oxygen demand (COD) and biological oxygen demand (BOD) by removing these substances.

Q3: In which industries are air flotation devices most commonly used?

Air flotation equipment is widely used in industries such as food processing (meat packing, dairy, seafood), petrochemical and refining, textile and dyeing plants, paper and pulp mills, municipal wastewater pretreatment, tannery and leather manufacturing, chemical, electroplating, pharmaceutical, and steel industries.

Q4: What are the main advantages of using air flotation technology over other wastewater treatment methods?

Key advantages include efficient removal of fine particles and emulsified oils, reduction of the load on secondary treatment systems, low chemical consumption, a compact structure requiring less space, energy-saving operation, improved sludge dewaterability, and reduced sludge volume. It also helps in removing odors and increasing dissolved oxygen.

Q5: Are there different types of air flotation devices?

Yes, according to the sources, air flotation can be categorized by the gas dissolution method, including aerated flotation machines and electrolytic flotation machines. The core principle of microbubble generation and pollutant adhesion remains central to these variations.

Q6: Can an air flotation device help with water reuse efforts?

Absolutely. By efficiently removing pollutants and clarifying water, an air flotation unit can bring wastewater closer to the quality required for industrial water reuse, enabling regulatory compliance and promoting sustainable water management practices.