Welcome to My Blog! 🌟

I’m so glad you’re here! Before we jump into the exciting content, I’d love for you to connect with me on my social media platforms. It’s where I share extra insights, interact with our amazing community, and post regular updates. Here’s how you can join the conversation:

📘 Facebook: Follow me on Facebook for more updates

Now, let’s dive into the journey ahead. I hope you find everything here both engaging and valuable. Together, let’s explore, learn, and grow! 🚀

Table of Contents

Introduction

Filter press sludge has become a growing concern in industries ranging from municipal wastewater treatment to food processing and mining. As regulations tighten and environmental standards increase, the need to manage filter press sludge efficiently has never been more pressing. Traditional sludge disposal methods are not only costly but also environmentally unsustainable. This article explores six smart and innovative solutions that are transforming how we deal with filter press sludge in 2025.

Solution 1: Automated Filter Press Systems

Automation plays a vital role in optimizing the filter press sludge process. Automated systems help minimize human error, enhance consistency, and reduce operational costs. These systems control parameters such as feed pressure, cycle time, and cake dryness levels with high precision.

Smart sensors integrated into the equipment allow for real-time monitoring of sludge characteristics and performance metrics. Automated filter press systems ensure uniform cake formation and reduce downtime associated with manual operations.

How Automation Works

Automated filter press systems are equipped with programmable logic controllers (PLCs) and smart sensors that continuously monitor and adjust operational parameters. These systems control:

- Feed pressure to maintain optimal flow rates and prevent press overloading

- Cycle time to balance dewatering efficiency and throughput

- Cake dryness to ensure sludge is sufficiently compact for easy disposal or reuse

Advanced models even include features like automatic plate shifters, high-pressure cloth washing systems, and hydraulic closure mechanisms—all aimed at reducing manual intervention.

Real-Time Monitoring and Data Analytics

Modern automated systems are often integrated with Industrial Internet of Things (IIoT) technology. This allows for:

- Remote monitoring and diagnostics

- Automated alerts and reporting

- Performance trend analysis over time

Operators can track key performance indicators (KPIs) such as cycle duration, energy consumption, and sludge volume reduction from a centralized control system or even a mobile device.

Benefits of Automation

- Lower Labor Costs: Reduced need for manual operation translates to savings in workforce expenses.

- Consistent Sludge Cake Quality: Automation eliminates variability, producing uniform sludge cakes with predictable moisture content.

- Enhanced Safety: By minimizing human interaction with press components, the risk of accidents and exposure to hazardous sludge is greatly reduced.

- Remote Monitoring and Control: Operators can supervise operations from remote locations, increasing flexibility and responsiveness.

By adopting automated systems, facilities not only improve process consistency but also position themselves for long-term operational resilience and scalability.

Solution 2: Sludge Dewatering Enhancements

Improving the dewatering process is essential for reducing the volume, weight, and handling complexity of filter press sludge. Effective dewatering directly influences operational costs, environmental impact, and the feasibility of downstream processing such as drying or resource recovery. Recent advancements in dewatering technology have enabled industries to achieve higher solids content in sludge cakes with minimal energy input.

Cutting-Edge Dewatering Technologies

Modern dewatering enhancements combine mechanical, chemical, and physical principles to achieve superior performance:

- Advanced Polymer Dosing Systems: These systems automatically adjust the polymer concentration based on sludge characteristics in real time. Proper dosing improves particle aggregation and enhances water release during filtration.

- Pre-Thickening Units: By concentrating the sludge before it reaches the filter press, units such as gravity belt thickeners or rotary drum thickeners increase overall throughput and reduce press cycle time.

- Vacuum-Assisted Filtration: This technique creates a pressure differential across the filter media, accelerating water removal and reducing residual moisture in the cake. It’s especially useful for sludge with fine particles or low permeability.

Operational and Environmental Gains

By increasing the solid content of the sludge cake, these enhancements provide several tangible benefits:

- Lower Moisture Levels: Dryer sludge cakes are lighter and require less volume, making them cheaper to store, transport, and dispose of.

- Improved Filter Press Efficiency: Thicker, more consistent feed sludge results in shorter press cycles and increased system capacity.

- Reduced Polymer Consumption: Intelligent dosing systems minimize chemical usage, which lowers costs and reduces environmental impact.

Strategic Value

For industries generating large volumes of sludge—such as mining, chemical manufacturing, and municipal wastewater treatment—enhancing dewatering processes is a cost-effective strategy to reduce operational load and environmental footprint. When implemented correctly, these enhancements not only boost performance but also extend the lifespan of the filter press system.

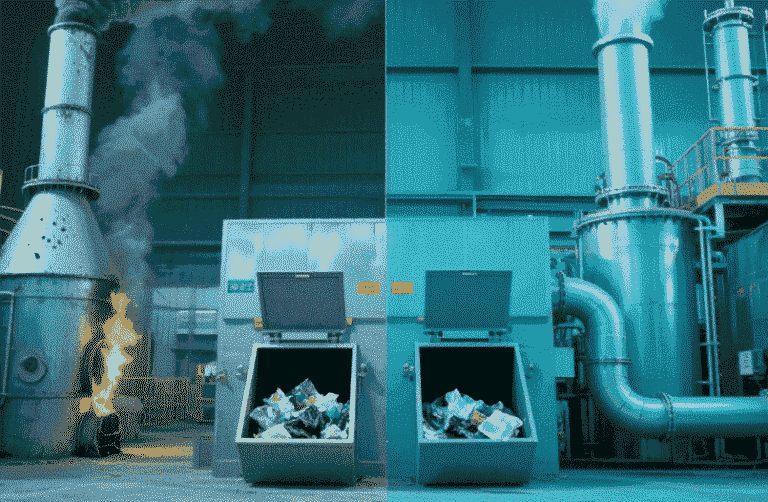

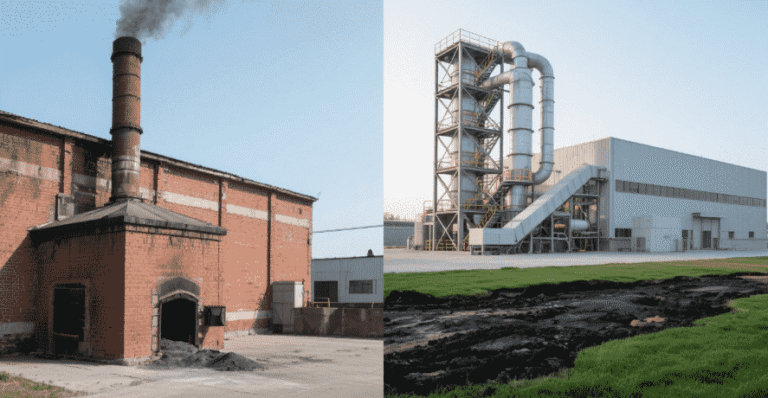

Solution 3: Energy Recovery from Filter Press Sludge

Energy recovery is one of the most forward-thinking approaches in modern filter press sludge management. Rather than viewing sludge as a waste product, this solution treats it as a resource with untapped energy potential. Filter press sludge, especially that generated by food processing, wastewater treatment, and organic industrial waste, often contains biodegradable components that can be converted into energy.

Technologies for Energy Recovery

Several methods have been developed to extract energy from filter press sludge, with each offering unique advantages depending on the type and consistency of the sludge.

- Anaerobic Digestion: This biological process breaks down organic material in the absence of oxygen. The result is biogas, which contains methane and can be used for heating or electricity generation. Digestate, the remaining material, can also be further treated or used as fertilizer.

- Thermal Drying Followed by Incineration: Drying the sludge before incineration increases combustion efficiency. This method is highly effective for reducing sludge volume and producing heat or electricity. It is especially useful when sludge contains high moisture levels post-dewatering.

- Gasification: In this process, organic sludge is exposed to high temperatures with a limited amount of oxygen. It produces syngas (a mix of hydrogen and carbon monoxide), which can power turbines or be used as chemical feedstock.

Economic and Environmental Benefits

Facilities that invest in energy recovery technologies from filter press sludge can achieve long-term savings and environmental compliance. Here’s how:

- Cost Reduction: By generating energy on-site, industries can lower their dependence on external power sources. Over time, this leads to a noticeable reduction in utility expenses.

- Waste Volume Reduction: These methods drastically decrease the mass and volume of sludge requiring disposal, reducing landfill fees and related logistics costs.

- Carbon Footprint Minimization: Replacing fossil fuels with recovered biogas or syngas contributes to a greener footprint and can help meet environmental regulatory standards.

Integration into Existing Operations

Energy recovery systems are increasingly designed to integrate seamlessly into existing filter press sludge handling processes. For instance, some modern anaerobic digesters are compact and modular, allowing for installation in limited spaces and gradual scaling as needed.

Industries dealing with large volumes of filter press sludge, such as municipal wastewater treatment facilities or paper mills, benefit significantly from this integration. Combined heat and power (CHP) units can further optimize the energy generated by capturing and reusing the heat from electricity production.

Solution 4: Sludge Cake Reuse and Resource Recovery

Filter press sludge often contains reusable resources like metals, nutrients, and organic matter. Innovative recovery techniques include:

- Metal extraction from industrial sludge

- Nutrient recovery for use as agricultural fertilizer

- Construction material production from dried sludge cakes

These methods turn a waste problem into a resource opportunity, aligning with global sustainability goals.

Table: Comparative Analysis of Filter Press Sludge Solutions

| Solution | Cost Efficiency | Environmental Impact | Implementation Complexity | Long-Term Benefits |

|---|---|---|---|---|

| Automated Filter Press Systems | High | Medium | Medium | Consistent performance |

| Dewatering Enhancements | Medium | High | Medium | Lower disposal costs |

| Energy Recovery | Medium | High | High | Energy offset |

| Resource Recovery & Reuse | High | High | High | Revenue generation |

| Sludge Thickening Optimization | Medium | Medium | Low | Increased efficiency |

| AI-Based Monitoring Systems | High | High | Medium | Real-time decisions |

Solution 5: Sludge Thickening Optimization

Before the filter press stage, thickening the sludge can drastically reduce the volume that needs to be processed. Gravity thickeners, dissolved air flotation (DAF) systems, and rotary drum thickeners are commonly used.

Thickened sludge improves filter press efficiency by reducing cycle times and increasing cake dryness. This step also allows for more effective polymer usage and reduced energy consumption.

Solution 6: AI-Based Monitoring and Predictive Maintenance

Artificial intelligence and machine learning technologies are redefining filter press sludge management. AI-based systems analyze historical and real-time data to predict equipment failure, optimize dosing rates, and fine-tune operational parameters.

Key AI Applications:

- Predictive maintenance alerts

- Optimal cycle time adjustments

- Anomaly detection in sludge behavior

These tools enable proactive decision-making, reduce unplanned downtime, and improve overall process efficiency.

Conclusion

The growing challenges of environmental regulations and rising disposal costs demand innovative approaches to managing filter press sludge. The six smart solutions discussed in this article—automation, enhanced dewatering, energy recovery, resource reuse, thickening optimization, and AI-based monitoring—offer scalable and sustainable options for various industries.

Implementing these solutions not only helps reduce costs but also supports environmental compliance and long-term operational efficiency. As technology continues to evolve, filter press sludge management will become more intelligent, sustainable, and economically viable.

FAQ

What is the most cost-effective way to manage filter press sludge?

Dewatering enhancements and thickening optimization are among the most cost-effective methods. They reduce sludge volume and lower transport and disposal costs.

Can filter press sludge be reused?

Yes, depending on its composition. Sludge containing metals, nutrients, or organic matter can be processed for reuse in agriculture, construction, or energy production.

Is automation necessary for managing filter press sludge?

While not mandatory, automation greatly improves consistency, safety, and efficiency. It is especially beneficial for large-scale operations.

How does AI help in sludge management?

AI analyzes data to optimize operations, predict equipment failure, and enhance performance. It reduces downtime and maintenance costs.

What are the environmental benefits of smart sludge solutions?

These solutions reduce landfill waste, recover valuable resources, and minimize energy usage—helping industries meet sustainability goals.