Welcome to My Blog! 🌟

I’m so glad you’re here! Before we jump into the exciting content, I’d love for you to connect with me on my social media platforms. It’s where I share extra insights, interact with our amazing community, and post regular updates. Here’s how you can join the conversation:

📘 Facebook: Follow me on Facebook for more updates

Now, let’s dive into the journey ahead. I hope you find everything here both engaging and valuable. Together, let’s explore, learn, and grow! 🚀

Table of Contents

Introduction

Sustainable development is a multidimensional concept that emphasizes the balanced integration of environmental protection, economic growth, and social well-being. In the realm of environmental sustainability, wastewater and sludge treatment play an increasingly critical role. With the escalating challenges posed by industrial discharge and urban wastewater, innovative sludge dewatering equipment offers powerful solutions that align with sustainable development goals. This article explores six transformative pieces of sludge equipment—Integrated Buried Sewage Treatment, Air Flotation Machine, Anaerobic Tower, Inclined Tube Sedimentation Equipment, Screw Press, and Grease Trap—and examines how each contributes meaningfully to sustainable development.

Integrated Buried Sewage Treatment: A Compact Solution for Sustainable Development

The Integrated Buried Sewage Treatment system is a modern solution that combines biological and physicochemical processes in a compact underground structure. It is particularly suited for densely populated or space-constrained urban environments. This type of system typically involves several treatment stages, including screen deslagging, a regulating tank, biological decomposition (utilizing activated sludge or membrane bioreactor technology), sedimentation with sludge return, and final disinfection.

How It Works

Initially, large debris and suspended solids are removed in the screening chamber. The flow then enters a regulating tank that equalizes hydraulic and pollutant loads, ensuring stable conditions for subsequent biological treatment. In the biological treatment stage, microorganisms break down organic pollutants into harmless by-products like CO₂ and water. The sedimentation tank allows solid-liquid separation, returning a portion of the settled sludge to sustain the biological activity. The treated water is disinfected before being discharged or reused.

Key Benefits

- Space Efficiency: Since the entire system is buried underground, it minimizes land usage—a major advantage in urban redevelopment zones or areas where real estate is expensive.

- Energy Optimization: Leveraging biological processes reduces reliance on energy-intensive mechanical systems.

- Effluent Quality: The combination of advanced biological decomposition and disinfection produces high-quality effluent, often suitable for non-potable reuse in landscaping, industrial cooling, or agriculture.

Sustainable Development Impact

This system aligns with sustainable development by mitigating the environmental footprint of wastewater infrastructure. It enhances water recycling and conserves land resources while maintaining high treatment efficiency. Municipalities, hospitals, industrial parks, and schools can benefit from its compact design and low operational noise, making it both effective and community-friendly.

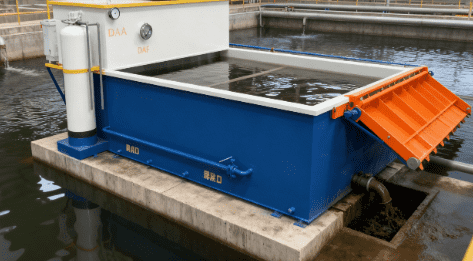

Air Flotation Machine: High-Speed Pollutant Removal for Sustainable Development

The Air Flotation Machine, also known as a Dissolved Air Flotation (DAF) unit, is a proven method for separating fine particulate matter, oils, and grease from wastewater. The core mechanism involves dissolving air into water under pressure, then releasing it at atmospheric pressure in a flotation tank. This causes microbubbles to form and adhere to suspended solids, lifting them to the surface.

How It Works

The air is pressurized and dissolved into the water via a saturation system. When this water is introduced into the flotation tank, it is depressurized, resulting in the rapid release of microbubbles. These bubbles attach to impurities, increasing their buoyancy. A scraper mechanism at the surface then collects the accumulated scum for further treatment or disposal.

Key Benefits

- Rapid Separation: Microbubble flotation significantly reduces processing time compared to traditional sedimentation methods.

- Lower Chemical Usage: While coagulants may still be used, the overall chemical demand is reduced thanks to effective flotation separation.

- Wide Applicability: Particularly beneficial for industries with oily or colloidal waste, such as food processing plants, oil refineries, and pulp mills.

Sustainable Development Impact

This equipment supports sustainable development through its high-speed, high-efficiency design. It enables industries to treat and reuse water with minimal ecological disruption. The reduction in chemical usage and sludge production also contributes to safer and more sustainable operations. As industries face stricter environmental regulations, the air flotation machine provides a reliable tool for compliance without compromising productivity.

Anaerobic Tower: Waste-to-Energy Conversion for Sustainable Development

The Anaerobic Tower represents a cornerstone in modern sludge treatment—converting organic waste into usable energy while reducing pollution. It employs a multi-stage microbial process that breaks down organic pollutants in the absence of oxygen. This process consists of three main phases: hydrolysis, acidogenesis, and methanogenesis.

How It Works

- Hydrolysis: Large organic molecules such as proteins and carbohydrates are broken down into simpler molecules by hydrolytic bacteria.

- Acidogenesis: These simpler molecules are further metabolized by acidogenic bacteria into volatile fatty acids, alcohols, and gases like hydrogen and CO₂.

- Methanogenesis: Methanogens convert these intermediate products into methane and carbon dioxide, which can be captured and used as biogas.

Key Benefits

- Energy Production: Methane generated can be harnessed to produce electricity or heat, reducing dependence on fossil fuels.

- Efficient COD Reduction: Anaerobic systems effectively remove chemical oxygen demand (COD) and reduce organic loading.

- Reduced Sludge Generation: Compared to aerobic treatment, anaerobic systems produce significantly less residual sludge, lowering disposal costs.

Sustainable Development Impact

This tower perfectly encapsulates the circular economy model central to sustainable development. It turns waste into a resource, lowers greenhouse gas emissions, and cuts operational costs. Particularly in agricultural, brewing, and food processing industries, anaerobic towers are integral to achieving both environmental and economic sustainability.

Inclined Tube Sedimentation Equipment: Accelerated Settling for Sustainable Development

Inclined Tube Sedimentation Equipment utilizes the principle of shallow-layer sedimentation to rapidly separate solids from liquids. This method enhances the effective sedimentation area without increasing the footprint of the tank.

How It Works

The equipment contains multiple closely spaced tubes or plates set at a 60-degree angle. When wastewater flows through these tubes, solids settle on the inclined surfaces and slide down due to gravity. Meanwhile, clarified water flows upward and overflows for further treatment or discharge.

Key Benefits

- Compact Design: The inclined tube design significantly reduces the required area compared to traditional sedimentation tanks.

- Low Maintenance: With fewer mechanical components, the system is easy to maintain and cost-effective.

- Short Retention Time: The process quickly achieves high levels of solids removal, supporting high-throughput treatment systems.

Sustainable Development Impact

This system enables wastewater treatment plants to improve their efficiency without expanding physical infrastructure. It contributes to sustainable development by conserving space, energy, and resources. It is especially suitable for retrofitting older treatment plants or integrating into mobile treatment units in rural or emergency settings.

Comparative Table: Contribution of Sludge Equipment to Sustainable Development

| Equipment | Key Process | Environmental Benefit | Space Saving | Energy Efficiency | Water Reuse Potential |

|---|---|---|---|---|---|

| Integrated Buried Sewage Treatment | Biological + Physicochemical | Reduces pollutant discharge, promotes reuse | Yes | High | High |

| Air Flotation Machine | Microbubble flotation | Rapid removal of pollutants | Moderate | Medium | Moderate |

| Anaerobic Tower | Anaerobic digestion to methane | Produces renewable energy, reduces COD | Moderate | High | Low |

| Inclined Tube Sedimentation | Gravity-based solid-liquid separation | Increases sedimentation rate, reduces space use | High | High | Moderate |

| Screw Press | Gravity + mechanical dewatering | Produces low-moisture sludge for easier disposal | High | High | Low |

| Grease Trap | Oil-water separation | Prevents oil pollution, reduces treatment load | Moderate | Medium | Low |

Screw Press: Minimizing Sludge Volume for Sustainable Development

The Screw Press utilizes gravity to remove free water followed by mechanical compression to eliminate interstitial and bound water. The result is a low-moisture-content sludge cake.

Key Benefits

- High Dryness Output: Reduces transportation and disposal costs.

- Continuous Operation: Suitable for industrial-scale processes.

- Energy Conservation: Minimal heat or chemical use.

By significantly reducing sludge volume, the Screw Press contributes to sustainable development through lower logistical demands and environmental risks associated with sludge management.

Grease Trap: First-Line Defense for Sustainable Development in Wastewater Treatment

Grease Traps separate oil and grease from wastewater using physical or chemical means. They are especially important in food service and industrial settings.

Key Benefits

- Protects Equipment: Prevents clogging and corrosion in downstream systems.

- Improves Treatment Efficiency: Reduces load on subsequent treatment stages.

- Regulatory Compliance: Helps meet effluent standards.

As a first-stage device, the grease trap plays a crucial role in ensuring the integrity of wastewater treatment, aligning with sustainable development goals of pollution prevention.

Conclusion

Each of the six sludge treatment technologies outlined plays a vital role in supporting sustainable development. By improving water reuse, reducing pollution, optimizing space and energy use, and in some cases generating renewable energy, these machines bridge the gap between industrial efficiency and ecological responsibility. Integrated solutions combining these technologies can offer municipalities and industries an effective path toward cleaner water and a more sustainable future.

For decision-makers and engineers aiming to upgrade their treatment systems, these powerful tools are more than equipment—they are catalysts for sustainable development.

FAQ

What is the most sustainable sludge treatment method?

Anaerobic digestion in Anaerobic Towers is particularly sustainable due to its energy recovery and high pollutant removal.

Can these machines be used together?

Yes. An optimal sludge treatment system often integrates multiple technologies such as grease traps, air flotation, and screw presses for comprehensive performance.

How does sludge equipment align with sustainability goals?

These technologies promote cleaner water, energy conservation, waste reduction, and resource recovery—core tenets of sustainable development.

Are these systems scalable?

Absolutely. The modular design of most sludge equipment allows for scalable solutions that fit both small and large-scale operations.

Do these machines require a lot of maintenance?

Most of these devices are designed for reliability and low maintenance, though regular inspections and basic upkeep are recommended to ensure optimal performance.