Table of Contents

Introduction

In the vibrant world of culinary arts and food manufacturing, the delicious outputs often come with a less savory byproduct: wastewater. Restaurants, catering businesses, and especially food factories generate a significant volume of wastewater that is uniquely challenging due to its high content of grease, organic matter, and suspended solids. This “greasy wastewater” poses significant environmental risks and can be a costly hurdle for businesses striving to comply with stringent discharge standards. But what if there was a way to turn this challenge into an opportunity for green production and economic benefit?

At Shandong Lushun Environmental Technology Co., Ltd., we specialize in high-tech environmental protection products, focusing on comprehensive wastewater treatment solutions. We bring you our “Cleaning Magic” – advanced food wastewater treatment equipment designed to efficiently purify even the most challenging industrial and catering wastewater, ensuring compliance, enabling water reuse, and fostering sustainable operations.

The Challenge of Food & Restaurant Wastewater

Restaurant wastewater and food wastewater are notoriously complex. Unlike typical domestic sewage, they are characterized by elevated levels of:

• Grease and Oils: From cooking fats, oils, and general food preparation, these substances can clog pipes, interfere with treatment processes, and are difficult to degrade.

• High Organic Load: Food scraps, dissolved organic compounds, and biochemical oxygen demand (BOD) are abundant, demanding robust biological treatment.

• Suspended Solids: Food particles, residues, and other non-dissolved materials contribute to turbidity and require effective physical separation.

Without proper grease treatment and wastewater purification, these effluents can lead to severe environmental pollution, including contamination of water bodies and harm to aquatic ecosystems. Furthermore, non-compliance with discharge regulations can result in heavy fines and damage to a company’s reputation. This is where specialized, efficient wastewater treatment for food factories becomes not just a necessity, but a strategic asset.

Our “Cleaning Magic”: The Three-Stage Treatment Process for Wastewater Treatment for Food Factories

Our state-of-the-art food wastewater treatment equipment employs a sophisticated three-stage treatment process to efficiently remove organic matter, grease, and suspended solids. This integrated approach ensures thorough purification, meeting the highest discharge standards, and facilitating water reuse.

Stage 1: Pretreatment – Tackling Grease and Suspended Solids

The initial stage focuses on removing the most problematic components: grease and large suspended solids. This is crucial for protecting subsequent treatment stages from clogging and inefficiency. Key technologies often integrated here include:

• Grease Traps and Skimmers: These physical separation units are designed to capture and remove fats, oils, and grease (FOG) at the source, preventing them from entering the main treatment stream.

• Screens and Sedimentation Tanks: Coarse screens remove larger solid particles, while sedimentation tanks allow denser suspended solids to settle out.

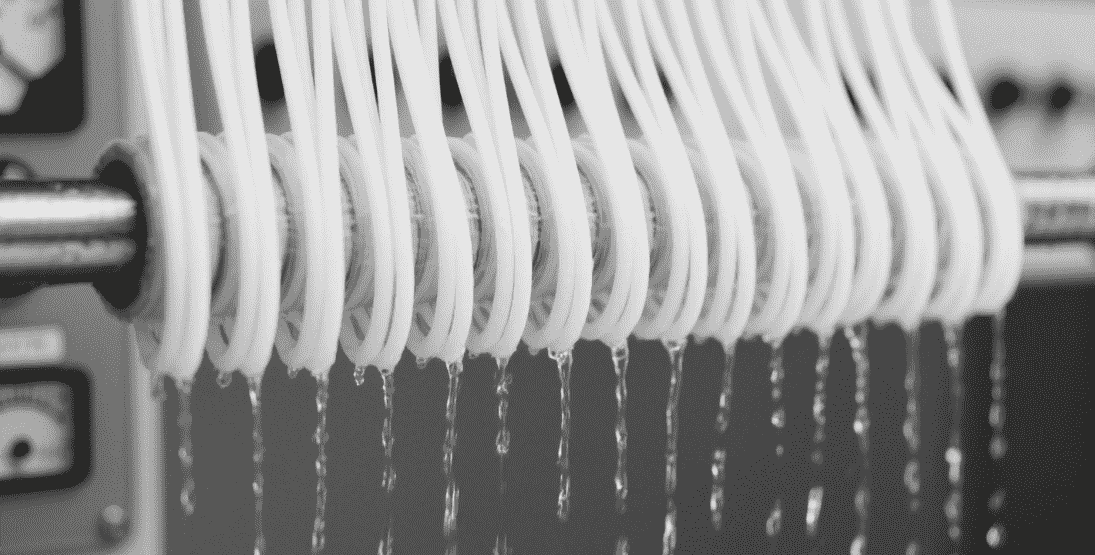

• Flotation Equipment: For more challenging effluents, especially those with emulsified oils and fine suspended solids, flotation machines act as a “bubble magician”. They achieve efficient solid-liquid separation by introducing microbubbles that attach to suspended matter, causing it to float to the surface for easy removal. This is particularly effective for grease treatment in restaurant wastewater.

Stage 2: Biochemical Treatment – Degrading Organic Matter

Following pretreatment, the wastewater enters the biochemical treatment phase, where biological processes are leveraged to degrade dissolved organic matter. This stage is the heart of wastewater purification for high organic load effluents:

• Anaerobic Treatment: This method utilizes anaerobic microorganisms to degrade macromolecular organic matter in wastewater. Hydrolytic bacteria break down complex organics into simpler compounds like monosaccharides, amino acids, and fatty acids. Acidogenic bacteria then convert these into volatile fatty acids, alcohols, and carbon dioxide. Finally, methanogenic bacteria transform these into methane and carbon dioxide. This process not only effectively removes organic matter but also offers the unique benefit of energy recovery in the form of biogas.

• Aerobic Treatment (Biofilm and Activated Sludge Processes): These processes use aerobic microorganisms, often in systems like biofilm reactors or activated sludge tanks, to break down remaining organic compounds and remove nitrogen and phosphorus. The microorganisms consume organic pollutants as a food source, converting them into harmless byproducts and more biomass. This robust biological activity is fundamental for comprehensive wastewater purification.

Stage 3: Advanced Membrane Filtration – Ensuring Purity and Reuse

The final stage of our “Cleaning Magic” involves advanced membrane filtration systems, ensuring the highest level of purification. This step is critical for meeting stringent discharge standards and, more importantly, for enabling water reuse.

• Membrane Bioreactors (MBRs): Integrating membrane separation with biological treatment, MBRs offer superior effluent quality, allowing for the reuse of grey water. MBRs provide an efficient barrier against suspended solids, bacteria, and even some viruses, resulting in water suitable for various non-potable applications.

• Ultrafiltration (UF) and Reverse Osmosis (RO): For specific applications requiring very high purity water, these advanced membrane technologies can further polish the effluent, removing dissolved salts, microscopic particles, and other contaminants, making the water suitable for process reuse or other high-grade applications.

By integrating pretreatment, biochemical, and membrane filtration systems, our wastewater treatment for food factories ensures not only compliance but also promotes a truly circular economy by allowing for water reuse.

Specialized Solutions for Diverse Needs

Our expertise extends across various sectors within the food industry, providing tailored efficient wastewater treatment for the meat and protein industry, wastewater treatment for dairy and cheese industry, and comprehensive sewage treatment equipment.

Efficient Wastewater Treatment for the Meat and Protein Industry

The meat and protein industry presents unique wastewater challenges, including high concentrations of blood, fats, proteins, and suspended solids, leading to high BOD and COD levels. Our specialized solutions for this sector leverage advanced pretreatment to handle large solid loads and fats, followed by robust biological treatment (both anaerobic and aerobic) to effectively break down proteins and other organic compounds. This integrated approach ensures the efficient removal of contaminants, significantly reducing the environmental impact and enabling the industry to achieve compliance with strict environmental regulations. The flotation equipment is particularly beneficial here for effective grease and solid separation.

Wastewater Treatment for Dairy and Cheese Industry

Wastewater from dairy and cheese production is typically characterized by high organic loads, milk fats, lactose, proteins, and elevated pH fluctuations. Our tailored wastewater treatment for dairy and cheese industry solutions address these specific challenges. We implement optimized pretreatment stages to manage fats and solids, followed by powerful biological processes that are designed to effectively degrade the unique organic compounds found in dairy effluents. The combination of anaerobic and aerobic biological processes ensures comprehensive breakdown of lactose and proteins, leading to purified water that meets discharge standards, all while striving for energy efficiency and operational simplicity.

Beyond Food: Comprehensive Sewage Treatment Equipment

While our focus here is on food processing, our capabilities extend to general sewage treatment equipment. For decentralized scenarios such as communities and hotels, our domestic sewage treatment equipment utilizes biofilm and activated sludge processes to degrade organic matter, nitrogen, and phosphorus. Integrating septic tanks and MBR membrane tanks, it enables the reuse of grey water through automated control, offering energy-saving and environmentally friendly characteristics. This demonstrates our broad expertise in wastewater purification for various needs.

Smart Technology and Sustainable Practices

At Shandong Lushun Environmental Technology Co., Ltd., innovation drives us. Our industrial wastewater treatment equipment features intelligent control and monitoring systems, guaranteeing compliance with discharge standards and enabling water reuse, thus promoting sustainable and eco-friendly production.

Intelligent Control and Monitoring

Our systems are equipped with intelligent control and monitoring systems that automate operations, optimize performance, and provide real-time data. This smart technology ensures efficient processing, reduces the need for manual intervention, and allows for precise adjustments, leading to consistent effluent quality and significant operational savings. This full-process automation ensures high efficiency and low cost, becoming an “underground guard” for the ecological environment.

Sludge Management: An Integral Part of Wastewater Purification

Effective sludge management is an often-overlooked but critical component of any comprehensive wastewater purification system. Our solutions include advanced sludge dewatering equipment, which is vital for reducing the volume of sludge and facilitating its safe disposal or reuse.

• Gravity and Pressure Filtration: After the sludge is fed, it is initially dehydrated by gravity on a filter belt. It then enters a pressing area where upper and lower filter belts are pressed by multiple sets of rollers to gradually squeeze out water, forming a mud cake with low moisture content. This completes the solid-liquid separation.

• Screw Stackers: These devices are quietly revolutionizing sludge treatment. Through bionic design and intelligent control, the screw stacker achieves sludge reduction and harmless treatment, becoming an important equipment for water environment management. This “intelligent nutritionist” in the field of sludge dewatering ensures that even the byproducts of wastewater treatment are handled in an environmentally responsible manner.

These integrated technologies contribute to a holistic approach to environmental protection, minimizing waste and maximizing resource recovery, aligning perfectly with the principles of green production and a circular economy.

Benefits of Choosing Our Solutions for Green Production

Our commitment to innovation and sustainability translates into tangible benefits for businesses utilizing our food wastewater treatment equipment:

• Efficient Contaminant Removal: Our systems efficiently remove organic matter, grease, and suspended solids, ensuring cleaner discharge.

• Guaranteed Compliance: With intelligent control and advanced technologies, our equipment guarantees compliance with all relevant discharge standards.

• Valuable Water Reuse: The capability for water reuse (e.g., grey water for non-potable applications) significantly reduces fresh water consumption and operational costs.

• Energy Savings and Low Maintenance: Designed for high efficiency and energy savings, our solutions also boast low energy consumption and easy maintenance, contributing to lower operating expenses.

• Promotion of Sustainable and Eco-Friendly Production: By effectively treating wastewater and enabling reuse, we help businesses achieve a win-win in environmental protection and economic benefits, fostering sustainable development and green production.

• Solving Catering Wastewater Pollution: Our specialized solutions directly address the unique challenges of catering and food industry wastewater, offering a reliable path to pollution prevention and control.

Conclusion

The challenges posed by greasy, organic-rich wastewater from restaurants and food factories are significant, but with our “Cleaning Magic,” they are entirely manageable. Shandong Lushun Environmental Technology Co., Ltd. provides advanced, high-tech wastewater treatment for food factories that integrates pretreatment, biochemical processes, and membrane filtration into a powerful, three-stage solution. This comprehensive approach ensures the efficient removal of grease, organic matter, and suspended solids, allowing enterprises to effortlessly meet discharge standards, embrace water reuse, and achieve significant savings in energy and maintenance.

By choosing our solutions, you’re not just investing in superior wastewater purification; you’re investing in green production, sustainable development, and a cleaner future for our planet. Let us help you transform your wastewater challenge into an opportunity for environmental leadership and economic growth.

FAQ

Q1: What types of wastewater can your equipment treat?

A1: Our company specializes in a wide range of wastewater treatment solutions, including industrial, domestic, hospital, and food wastewater treatment systems. This includes specific applications like efficient wastewater treatment for the meat and protein industry and wastewater treatment for dairy and cheese industry.

Q2: How does the three-stage process for food wastewater treatment work?

A2: Our food wastewater treatment equipment adopts a three-stage treatment process: pretreatment (for grease and suspended solids removal, often using flotation), biochemical treatment (for organic matter degradation via anaerobic and aerobic processes), and membrane filtration systems (for final purification and water reuse).

Q3: What are the benefits of water reuse in industrial settings?

A3: Water reuse, a key capability of our advanced systems, offers numerous benefits. It significantly reduces fresh water consumption, lowers operational costs, minimizes discharge volumes, and promotes sustainable development and green production within your facility.

Q4: Is your equipment energy-efficient and easy to maintain?

A4: Yes, our equipment is designed with high efficiency and energy savings in mind, and our food wastewater treatment equipment specifically highlights low energy consumption and easy maintenance. Our intelligent control and monitoring systems further optimize performance and reduce operational complexities.

Q5: How do you handle sludge generated during the wastewater treatment process?

A5: Sludge management is an integral part of our solutions. We offer specialized sludge dewatering equipment that combines gravity filtration with pressure filtration to form a mud cake with low moisture content. Additionally, our “screw stacker” technology is an “intelligent nutritionist” in the field of sludge dewatering, revolutionizing sludge reduction and harmless treatment.

Q6: What is the role of anaerobic treatment in your systems?

A6: Anaerobic treatment is a crucial biochemical stage where anaerobic microorganisms degrade macromolecular organic matter into simpler compounds, eventually producing methane and carbon dioxide. This process is highly effective for removing organic matter and offers the added benefit of energy recovery.

Q7: Can your solutions help my enterprise comply with specific discharge standards?

A7: Absolutely. Our industrial wastewater treatment equipment, including our food wastewater solutions, is equipped with intelligent control and monitoring systems that are designed to guarantee compliance with relevant discharge standards, promoting sustainable and eco-friendly production.