Managing waste efficiently and safely is a pressing challenge for municipalities, healthcare facilities, industrial plants, and hazardous waste handlers. Selecting the right incinerator type is crucial to ensure complete destruction of pathogens, safe disposal of chemicals, and compliance with environmental regulations. This guide explores various incinerator types, operational principles, applications, and practical considerations for choosing the most suitable system.

Table of Contents

Understanding Incinerators and Their Role in Waste Management

The Concept of Waste Incineration

An incinerator is a device designed to thermally treat waste at high temperatures, typically between 850–1200°C, converting it into sterile ash, carbon dioxide, and water vapor. By applying controlled combustion, incinerators significantly reduce waste volume, neutralize pathogens, and prevent chemical contamination. Unlike landfills or open burning, incineration provides a safe, controlled, and environmentally regulated disposal method.

Why Waste Incineration Matters

Proper incineration protects public health, reduces landfill dependency, and, in some cases, allows energy recovery. Hospitals, industrial plants, and municipal facilities rely on incinerators to manage complex and hazardous waste streams efficiently. Without appropriate incineration, infectious agents, toxic chemicals, and bulky waste pose significant environmental and operational risks.

Key Functions of Modern Incinerators

High-Temperature Combustion

Modern incinerators maintain temperatures high enough to completely oxidize organic compounds. This ensures that pathogens and chemical residues are fully neutralized.

Pathogen and Chemical Neutralization

Medical and hazardous waste incinerators are particularly important for eliminating bacteria, viruses, and pharmaceutical residues, preventing cross-contamination and environmental hazards.

Waste Volume Reduction

Incineration can reduce the physical volume of waste by up to 90%, lowering transportation costs and reducing the burden on storage facilities.

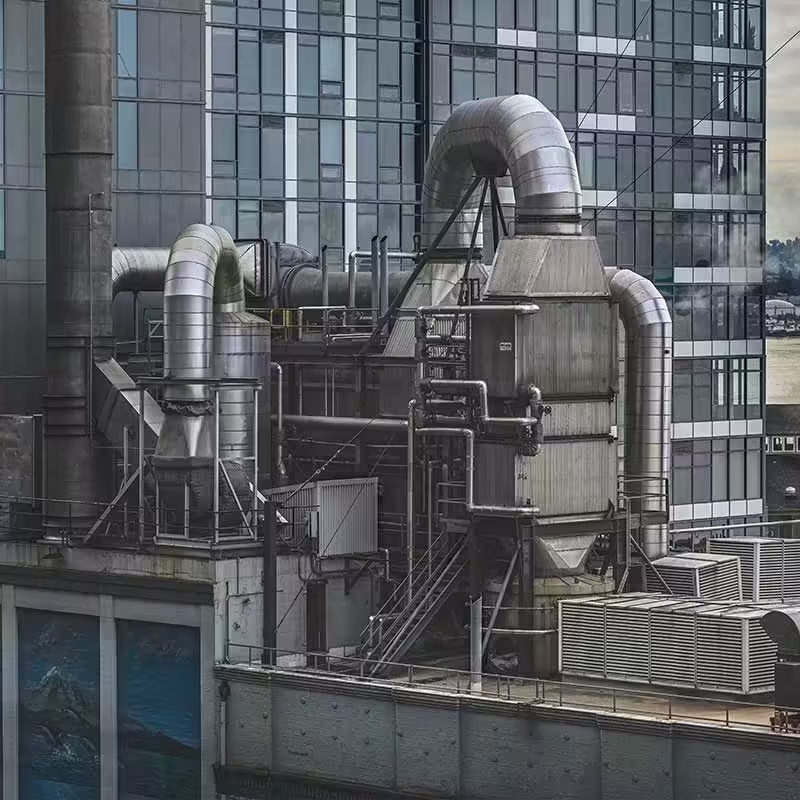

Emission Control and Environmental Compliance

Advanced incinerators incorporate scrubbers, filters, and secondary combustion chambers to limit particulate emissions, NOx, and other pollutants. This ensures compliance with local and international environmental standards.

Types of Incinerators and Their Applications

Municipal Solid Waste (MSW) Incinerators

MSW incinerators process city and residential waste, offering volume reduction and potential energy recovery. They are essential for urban waste management and landfill diversion.

Mass Burn Incinerators

These systems handle unsorted municipal waste, suitable for large-scale daily processing. They provide stable operation with moderate emission controls.

Refuse-Derived Fuel (RDF) Incinerators

RDF incinerators convert preprocessed waste into fuel pellets, increasing energy efficiency and reducing environmental impact compared to standard mass burn units.

Medical Waste Incinerators

Medical incinerators target infectious, chemical, and pharmaceutical waste from hospitals, laboratories, and clinics. They operate under strict temperature control to ensure pathogen elimination and chemical detoxification.

Single-Chamber Medical Incinerators

Compact and suitable for small facilities, single-chamber systems provide basic waste processing with moderate emission control.

Double-Chamber Medical Incinerators

Designed for large hospitals, these units feature a secondary combustion chamber, ensuring complete oxidation and higher environmental compliance.

Mobile Medical Incinerators

Portable solutions for remote or temporary healthcare units, enabling on-site hygienic waste treatment without centralized facilities.

Industrial Waste Incinerators

Industrial incinerators are engineered for chemical, pharmaceutical, and manufacturing byproducts. They prioritize operational safety, high thermal efficiency, and emission management.

Rotary Kiln Incinerators

Cylindrical, rotating chambers allow uniform combustion, ideal for heterogeneous industrial waste containing solid, liquid, or mixed components.

Fluidized Bed Incinerators

Waste is suspended in a fluidized sand bed, ensuring high combustion efficiency. Suitable for industrial streams with varying particle sizes and chemical properties.

Hazardous Waste Incinerators

High-risk chemicals and toxic materials require incinerators with strict temperature and emission control.

High-Temperature Hazardous Waste Incinerators

Operate at extremely high temperatures to ensure total detoxification of volatile organic compounds and persistent chemicals.

Plasma Arc Incinerators

Use plasma torches for ultra-high temperature combustion, suitable for low-volume, high-toxicity waste that cannot be processed by conventional methods.

Comparing Incinerator Types: Performance and Application

| Incinerator Type | Waste Type Handled | Temperature Range (°C) | Daily Capacity (kg) | Volume Reduction | Emission Control | Typical Applications |

|---|---|---|---|---|---|---|

| Mass Burn MSW | Municipal solid waste | 850–1100 | 10,000–50,000 | High | Basic | Urban waste management, landfills |

| RDF Incinerator | Preprocessed municipal waste | 900–1150 | 5,000–30,000 | High | Moderate | Waste-to-energy, energy recovery |

| Single-Chamber Medical | Hospital/clinic waste | 850–1000 | 50–200 | Medium | Basic | Small hospitals, clinics |

| Double-Chamber Medical | Hospital/clinic/pharma waste | 900–1200 | 200–1000 | High | Advanced | Large hospitals, labs |

| Rotary Kiln Industrial | Chemical/industrial waste | 900–1250 | 500–5000 | High | Advanced | Industrial plants, chemical waste |

| Fluidized Bed Industrial | Heterogeneous industrial waste | 850–1200 | 200–2000 | Medium | Advanced | Manufacturing facilities |

| Plasma Arc Hazardous | Toxic/chemical waste | 2000+ | 50–500 | Very High | Advanced | Specialized labs, high-toxicity waste |

This table allows facility managers to compare efficiency, capacity, and environmental compliance, helping them select the most suitable incinerator type for their waste profile.

Benefits of Using the Right Incinerator Type

Enhanced Safety and Hygiene

Choosing the appropriate incinerator ensures complete pathogen destruction, significantly reducing infection and cross-contamination risks in medical and industrial environments.

Efficient Waste Volume Reduction

Proper incineration reduces physical waste volume, simplifying storage and transport logistics, while decreasing overall operational costs.

Regulatory Compliance

Advanced incinerators meet environmental and safety standards, ensuring legal compliance and minimizing liability risks.

Energy Recovery Potential

Some incinerators, particularly RDF and certain MSW units, capture energy from combustion, generating electricity or heat and improving sustainability.

Operational Efficiency

Automating waste disposal streamlines workflows, reduces manual handling, and allows consistent waste processing across various facility types.

How to Choose the Best Incinerator Type

Evaluate Waste Characteristics

The composition, toxicity, and volume of waste determine the optimal incinerator type. Medical, hazardous, and industrial waste require specialized systems.

Consider Capacity and Throughput

Daily waste generation and peak load must match the incinerator’s thermal capacity to avoid processing bottlenecks.

Emission and Environmental Considerations

Facilities must consider air quality standards, pollutant emissions, and available technologies such as scrubbers, filters, and secondary combustion chambers.

Maintenance and Operational Cost

Modular and accessible designs simplify routine maintenance, reduce downtime, and lower long-term operational costs.

Space and Installation Requirements

Facility layout, floor space, and accessibility are crucial to ensure proper installation and operation.

Industry Applications

Municipal Waste Management

MSW incinerators provide urban waste reduction and energy recovery, preventing landfills from reaching capacity.

Healthcare and Medical Facilities

Medical incinerators are critical for pathogen destruction, chemical detoxification, and regulatory compliance in hospitals, clinics, and laboratories.

Industrial Plants

Rotary kiln and fluidized bed incinerators efficiently manage chemical and industrial byproducts, ensuring workplace safety.

Hazardous Waste Treatment

Plasma arc and high-temperature units neutralize high-toxicity and low-volume waste, meeting stringent environmental standards.

Remote and Mobile Applications

Mobile units provide hygienic and compliant waste disposal in rural or temporary healthcare setups.

FAQ

What is the difference between single and double-chamber incinerators?

Double-chamber units provide secondary combustion for complete oxidation and reduced emissions, suitable for larger hospitals or higher-risk waste streams.

Which incinerator type is best for municipal waste?

Mass burn and RDF incinerators efficiently handle city garbage while enabling potential energy recovery.

Can industrial incinerators safely process hazardous chemical waste?

Yes, rotary kiln, fluidized bed, and plasma arc incinerators are designed for safe industrial chemical disposal.

How do medical incinerators differ from municipal units?

Medical incinerators focus on pathogen elimination and chemical detoxification, whereas municipal units prioritize volume reduction and energy recovery.

What emission controls are standard for each incinerator type?

Advanced systems include scrubbers, filters, and secondary combustion chambers, while simpler units provide basic particulate control.

How do I determine the right capacity for my facility?

Calculate daily or peak waste generation and match it to the incinerator’s rated capacity to avoid overloading.

Are mobile incinerators suitable for remote areas?

Yes, they provide efficient, compliant, on-site waste disposal, especially in rural or temporary medical and industrial operations.

Conclusion

Selecting the correct incinerator type is essential for safe, efficient, and environmentally compliant waste management. Different facilities—municipal, medical, industrial, or hazardous—require tailored solutions to meet operational, safety, and environmental standards.

Contact us today to explore customized incinerator solutions and enhance your facility’s waste management practices.