Table of Contents

Introduction

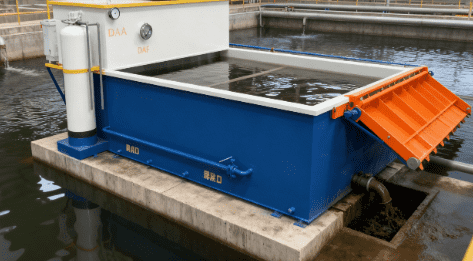

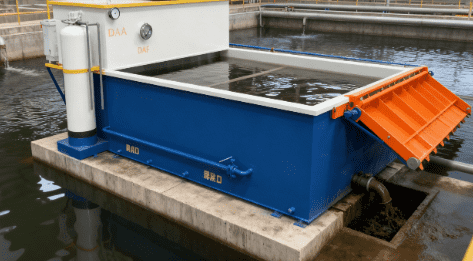

The Dissolved Air Flotation (DAF) Unit is a widely used wastewater treatment technology designed to remove suspended solids, oils, grease, algae, and low-density colloids that are difficult to settle through conventional sedimentation. By injecting air into water under high pressure, DAF forms microbubbles that attach to contaminants and lift them to the surface for mechanical removal.

DAF is commonly applied in industrial wastewater treatment, municipal water pretreatment, food processing, petrochemical plants, slaughterhouses, aquaculture, paper and pulp industries, and many more. Its ability to handle challenging wastewater while providing stable effluent makes it a cornerstone of modern water treatment systems.

How DAF Units Operate

Pressurization and Air Saturation

A portion of the treated water is recycled and pressurized in a saturation tank, typically at 4–7 bar. Air dissolves into the pressurized water, creating an air-rich solution ready for flotation.

Microbubble Formation and Contaminant Attachment

When the pressurized water enters the flotation tank, the sudden drop in pressure causes the dissolved air to form microbubbles (20–80 µm). These bubbles attach to suspended solids, oils, and flocs, effectively lowering their density.

Flotation and Skimming

Attached particles rise to the water surface forming a floating sludge layer. Mechanical skimmers continuously remove this layer while clarified water flows out for further treatment or discharge.

Chemical Integration for Enhanced Efficiency

Adding coagulants or flocculants such as PAC, ferric chloride, or polymers (PAM) enhances the aggregation of fine particles, increasing the attachment efficiency to microbubbles and improving overall DAF performance.

Components of a DAF Unit

Dissolved Air Tank

The saturation tank is a critical component that ensures proper air dissolution. Its design, material selection, and pressure regulation are essential for reliable operation.

Air Compressor and Pump

Air compressors supply air for the system, while pumps maintain the pressure necessary to saturate the recycled water stream. Both components require routine maintenance to ensure continuous operation.

Release Devices

Nozzles or release valves allow the pressurized water to expand, forming microbubbles uniformly. Proper design ensures maximum flotation efficiency.

Flotation Tank

DAF tanks can be rectangular or circular. The hydraulic retention time, water flow pattern, and lamella arrangements are carefully engineered to optimize separation efficiency.

Skimmer Mechanism

Skimmers remove floating sludge effectively. Chain, paddle, or scraper systems are common and designed to match tank size and sludge characteristics.

Chemical Dosing and Flocculation System

Rapid mixers, flocculation tanks, and dosing pumps are used to prepare and inject chemicals, improving particle aggregation before flotation.

Automation and Control

Modern DAF systems use PLC or SCADA controls for pump operation, chemical dosing, level monitoring, and skimmer management, enabling fully automated operation.

DAF Process Flow

The typical DAF treatment sequence begins with raw water inlet, followed by chemical coagulation to destabilize particles. Water then passes through a flocculation stage, where gentle mixing forms larger flocs. Recycled pressurized water is mixed, forming microbubbles and lifting contaminants. Skimmers remove the floating sludge, and clarified water exits the system for further treatment.

This flow ensures effective removal of suspended solids, oils, and other low-density pollutants while maintaining process stability.

Types of DAF Units

Standard Rectangular DAF units provide reliable performance for continuous operation.

High-Efficiency Shallow DAF designs offer higher loading rates and smaller footprints for plants with space limitations.

Package or Modular DAF Units are skid-mounted, compact, and ideal for small or decentralized treatment systems.

Hybrid DAF Systems integrate with biological treatment processes like A/O, MBR, or SBR to enhance overall wastewater treatment efficiency.

Advantages of Using DAF Units

DAF units are highly effective for removing low-density contaminants such as oils, grease, and algae. They provide stable effluent, occupy a compact footprint, and allow fast startup with easy automation. Their operation is cost-effective, consuming less energy and chemicals than many alternative technologies, and delivering consistent high removal efficiency.

Applications Across Industries

DAF systems are used in diverse industries:

Food and Beverage Processing

Removes fats, proteins, and suspended solids from meat, dairy, and beverage production wastewater.

Slaughterhouses and Rendering Plants

Handles high-strength organic wastewater efficiently.

Petrochemical Plants

Effective for separating emulsified oils and hydrocarbons.

Paper and Pulp Industry

Removes fibers, fillers, and coating residues.

Textile and Dyeing Industry

Treats colorants and fine solids.

Municipal Water Treatment

Pretreatment for algae-rich surface water.

Aquaculture and Fish Processing

Reduces organic matter and oils for discharge or reuse.

Key Design Parameters

A properly designed DAF unit balances hydraulic, chemical, and mechanical considerations. The table below summarizes typical design parameters:

| Parameter | Typical Range | Notes |

|---|---|---|

| Hydraulic Loading Rate | 5–12 m³/m²·h | Depends on wastewater type |

| Air-to-Solids Ratio (A/S) | 0.02–0.06 kg air/kg solids | Ensures effective flotation |

| Recycle Ratio | 10–30% | Portion of treated water recycled to saturation tank |

| Saturation Pressure | 4–7 bar | Higher pressure forms smaller microbubbles |

| Retention Time | 5–30 minutes | Shorter time in shallow tanks |

| Bubble Size | 20–80 µm | Smaller bubbles improve attachment efficiency |

| Chemical Dosage | Optimized PAC/PAM | Depends on particle characteristics |

This table helps engineers and operators select parameters that match wastewater characteristics and treatment goals.

Operation and Maintenance

Common operational challenges include insufficient microbubble formation, thin or thick sludge blankets, high effluent turbidity, short-circuiting, and skimmer malfunctions.

Troubleshooting strategies involve checking pump pressures, cleaning release valves, adjusting chemical dosing, and ensuring even water flow in the flotation tank.

Routine maintenance includes inspecting pumps and compressors, cleaning tanks and nozzles, lubricating skimmers, and calibrating chemical dosing systems. Regular maintenance ensures reliable performance and extends equipment lifespan.

Practical Case Study

A medium-sized slaughterhouse in Europe installed a high-efficiency shallow DAF system to treat wastewater with high fats, proteins, and suspended solids. After integrating chemical dosing with PAM and PAC, the DAF achieved:

- 95% removal of suspended solids

- 90% reduction in fats, oils, and grease

- Stable effluent meeting local discharge standards

This case illustrates how proper design, chemical integration, and operational control can optimize DAF performance for high-strength wastewater.

Selecting the Right DAF System

Choosing the appropriate DAF unit requires considering:

- Wastewater characteristics: oil content, suspended solids, COD/BOD, pH, and temperature

- Flow rates and capacity, accounting for peak conditions

- Available space and footprint constraints

- Desired effluent quality

- Automation requirements: PLC, SCADA, or manual operation

- Budget and lifecycle costs

Integrating these factors ensures reliable, cost-effective operation tailored to your specific wastewater treatment needs.

Comparison with Other Treatment Technologies

DAF is particularly advantageous for low-density contaminants that are difficult to settle. Compared to sedimentation, DAF provides faster and more reliable removal. In combination with filtration or membrane systems, DAF reduces load on downstream equipment. For emulsified oils and grease, DAF outperforms traditional oil separators or skimmers.

Conclusion

DAF units provide a versatile, efficient, and reliable solution for wastewater treatment across multiple industries. By removing low-density solids, oils, and greases while stabilizing downstream processes, DAF ensures compliant effluent quality. Proper design, operation, and maintenance are critical for long-term performance, and integration with chemical dosing or biological treatment can further enhance outcomes.

Need specific sizing or design recommendations? Contact our engineers to discuss the best DAF solution for your wastewater challenges.

FAQ

What contaminants can a DAF unit remove?

Oils, grease, suspended solids, algae, and fine colloids.

How important is microbubble size?

Smaller bubbles attach more effectively to particles, improving removal efficiency.

How often should DAF be maintained?

Routine maintenance is recommended monthly for small units, and weekly for high-load industrial applications.

Can DAF units handle municipal wastewater?

Yes, particularly as a pretreatment step for algae or high-SS water.

What chemicals are used in DAF systems?

Coagulants like PAC or ferric chloride, and flocculants like PAM, enhance floc formation and flotation efficiency.