Sludge management is one of the most critical aspects of wastewater treatment and industrial process operations. In municipal wastewater treatment plants (WWTPs), industrial chemical plants, mining operations, and food and beverage facilities, sludge can account for up to 40% of operational costs related to disposal, transport, and treatment. A poorly selected sludge dewatering machine not only increases operating costs but also risks regulatory non-compliance, environmental pollution, and operational downtime.

A modern sludge dewatering machine provides several essential benefits:

- Reduces sludge volume and moisture content, lowering transportation and landfill costs.

- Improves water recovery for reuse in industrial processes.

- Ensures compliance with environmental and discharge regulations.

- Enhances operational safety and reduces labor through automation.

This guide dives deep into all major types of sludge dewatering machines, their advantages, limitations, cost implications, and how to choose the right one for different sludge types.

Table of Contents

Key Takeaways of This Article

- Understand all major types of sludge dewatering machine and their working principles

- Learn real-world operational data and efficiency metrics

- Compare belt presses, screw presses, centrifuges, and filter presses for industrial and municipal applications

- Explore specialized sludge dewatering machines for mining, desilting, and industrial wastewater

- Understand maintenance, cost, and lifecycle considerations

- Get practical, Google AI-friendly FAQ answers reflecting real user search behavior

What Is a Sludge Dewatering Machine?

A sludge dewatering machine is a mechanical system designed to separate solids from liquid in sludge efficiently. The goal is not complete drying but substantial moisture reduction, producing a semi-solid sludge cake suitable for disposal, incineration, or reuse.

Core Functions of a Sludge Dewatering Machine

- Gravity Filtration: Removes free water in the initial stage.

- Pressure Filtration or Mechanical Compression: Extracts deeply trapped water.

- Solid-Liquid Separation: Ensures efficient division of solids and liquids.

- Automated Operation: Minimizes labor and maintains continuous operation.

- Sludge Cake Formation: Produces uniform, transportable, and environmentally safe sludge cakes.

Main Types of Sludge Dewatering Machine

Different machines operate on varying principles, each suitable for different sludge characteristics.

1. Belt Filter Press Sludge Dewatering Machine

Working Principle

The belt filter press is widely used in municipal and industrial wastewater plants. Sludge is evenly distributed on a moving filter belt where gravity removes free water. The partially dewatered sludge enters a series of rollers that apply progressive pressure, squeezing additional water out and forming a dense sludge cake.

Performance Metrics

- Moisture content of sludge cake: 65–75% solids

- Throughput: 2–150 m³/h depending on model and size

- Power consumption: 0.8–1.5 kWh/m³

Advantages

- Continuous operation

- Handles large volumes efficiently

- Automated for low labor input

- Stable sludge cake output

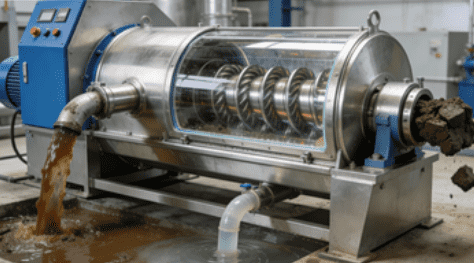

2. Screw Press Sludge Dewatering Machine

Concept

A screw press gradually compresses sludge inside a cylindrical chamber using a rotating screw. Water exits through a screen while solids move forward as a cake.

Data and Application

- Suitable for oily, organic, or fibrous sludge

- Sludge cake solids: 20–30% higher than some belt presses in oily sludge

- Compact design fits limited-space facilities

Pros and Cons

| Pros | Cons |

|---|---|

| Lower energy consumption | Less effective for extremely fine sludge |

| Simple structure | Batch or semi-continuous operation in some models |

| Low maintenance | May need pre-thickening for low-solid sludge |

3. Centrifugal Sludge Dewatering Machine

Working Principle

Sludge is spun at high speed in a centrifuge drum. Centrifugal force pushes heavier solids outward while water moves inward. Separation efficiency depends on rotational speed and feed solids concentration.

Performance Data

- Solid content after dewatering: 30–40% (typical)

- Rotational speed: 3,000–6,000 rpm

- Continuous operation possible, but energy consumption is high

Best Use Cases

- Fine-grained or chemically treated sludge

- Limited footprint applications

- Industrial facilities requiring rapid processing

4. Plate and Frame Filter Press Sludge Dewatering Machine

Concept

A batch-operated press using filter plates and cloths. Sludge is pumped into chambers and compressed under pressure, leaving solids trapped as a low-moisture cake.

Key Metrics

- Solids content of sludge cake: 70–85%

- Batch operation cycle: 30–90 minutes depending on feed

- Energy: Moderate; labor-intensive

Advantages

- Produces very dry sludge cakes

- High chemical resistance

- Ideal for high-value or hazardous sludge requiring extreme dryness

Specialized Belt Filter Press Sludge Dewatering Machines

Industrial Sludge Belt Filter Press

Overview

Used for municipal wastewater treatment, chemical plants, textile dyeing, and food/beverage industries. The dual-stage process (gravity + progressive roller pressure) efficiently reduces water content.

Data Example

- Machine dimensions: 13,000 × 3,000 × 2,600 mm

- Weight: 8,200 kg

- Processing capacity: 50–150 m³/h

Mine Sludge Belt Filter Press

Industrial Mining Application

Handles tailings, mineral slurries, and coal sludge. Supports water recovery and reduces environmental impact.

Key Advantages

- Continuous operation under harsh conditions

- Dense sludge cake with 70–75% solids

- Reduces tailing pond risk

Desilting Sludge Belt Filter Press

Sediment-Rich Sludge Handling

Ideal for dredging, urban drainage cleaning, and sediment-heavy industrial effluents.

Performance

- Produces compact mud cakes with 65–72% solids

- Continuous operation with minimal energy

- Reduces downstream sludge handling costs

Comparative Analysis of Sludge Dewatering Machines

| Machine Type | Continuous Operation | Cake Dryness | Energy Use | Best For |

|---|---|---|---|---|

| Belt Filter Press | Yes | 65–75% | Moderate | Municipal & Industrial |

| Screw Press | Semi | 60–70% | Low | Organic/oily sludge |

| Centrifuge | Yes | 30–40% | High | Fine/slime sludge |

| Plate & Frame | Batch | 70–85% | Moderate | Hazardous/high-value sludge |

Cost Considerations for Sludge Dewatering Machines

Capital Investment

- Small belt filter press: $15,000–$50,000

- Industrial belt filter press: $100,000–$350,000

- Centrifuge: $50,000–$200,000

- Plate & frame: $40,000–$150,000

Operational Costs

- Energy: 0.8–3 kWh/m³ depending on type

- Maintenance: 5–10% of capital per year

- Labor: Low for automated belt presses, higher for batch systems

ROI Example

- Municipal WWTP: Belt press reduces disposal volume by 50%, cutting transport costs $50,000/year

- Industrial mining: Screw press recovers 60–70% water for reuse, lowering fresh water cost

Selection Guidelines

- Sludge Characteristics: Particle size, organic content, and chemical composition

- Capacity Needs: Average and peak sludge volume

- Site Constraints: Space, utility availability, and lifting equipment

- Operational Cost & ROI: Energy, labor, maintenance, and disposal savings

- Compliance: Environmental and discharge regulations

Maintenance & Operational Best Practices

Daily

- Inspect belts, rollers, and screens

- Check hydraulic pressure and motor performance

- Clean filter cloths or screens

Weekly / Monthly

- Lubricate moving parts

- Check structural integrity

- Test cake dryness and adjust pressure

Annual

- Major overhaul of motors, bearings, and hydraulic systems

- Stack or effluent testing for regulatory compliance

Expert Perspectives

- EPA Guidelines: Emphasize controlled sludge volume reduction and solids recovery to minimize landfill burden.

- European Water Industry Studies: Belt filter presses are most cost-effective for municipal applications with >100 m³/day sludge.

- Mining Engineering Reports: Progressive pressure belt presses reduce tailings water content by 15–20% more than traditional screw presses.

Conclusion

Understanding types of sludge dewatering machine is critical for sustainable, efficient sludge management. By evaluating sludge characteristics, operational data, and cost factors, industrial facilities and municipal plants can select a machine that maximizes efficiency, reduces costs, and ensures environmental compliance.

A carefully chosen sludge dewatering machine is not just equipment—it is a long-term solution that safeguards operations, reduces environmental risk, and supports regulatory adherence.

FAQ

What is the most common type of sludge dewatering machine?

Belt filter presses dominate municipal and industrial applications due to continuous operation and adaptability.

How dry can sludge cakes get?

Moisture content ranges 25–40% depending on machine type and sludge characteristics.

Can one machine handle all sludge types?

No. Sludge dewatering machines must be matched to particle size, chemical composition, and water content.

How energy-intensive are these machines?

Centrifuges are high-energy; belt and screw presses are energy-efficient.

How to choose the right machine?

Consider sludge type, volume, disposal method, energy cost, and site conditions.