Table of Contents

A sludge dewatering machine plays a critical role in modern wastewater treatment by reducing sludge volume, lowering disposal costs, and improving overall plant efficiency. For municipal and industrial facilities, choosing the right sludge dewatering solution is not only a technical decision but also a long-term investment.

As an experienced sludge dewatering machine manufacturer, we have prepared this complete guide to help you understand how sludge dewatering machines work, how to select the right type, and how a reliable manufacturer can support your project from design to delivery.

What Is a Sludge Dewatering Machine?

A sludge dewatering machine is a mechanical device used to separate water from sludge, producing a solid cake with significantly reduced moisture content. This process minimizes sludge volume and makes transportation, disposal, or further treatment more economical.

This type of equipment is commonly applied in:

- Municipal sewage treatment facilities

- Industrial wastewater systems

- Food processing, chemical, textile, and pharmaceutical plants

Mechanical dewatering improves operational efficiency while supporting environmental protection goals.

How Does a Sludge Dewatering Machine Work?

Although equipment designs vary, the dewatering process generally follows the same basic steps.

Sludge Conditioning and Flocculation

Before dewatering begins, sludge is conditioned using polymer agents to form stable flocs. Proper flocculation improves solid–liquid separation and helps achieve better cake dryness.

Mechanical Separation Process

Conditioned sludge then enters the dewatering zone, where pressure, gravity, or centrifugal force is applied. Water is separated and discharged, while the solid phase is collected for further treatment or disposal. Automated operation ensures consistent performance and stable output.

Types of Sludge Dewatering Machines and Their Applications

Different sludge properties require different dewatering technologies. The most commonly used systems include:

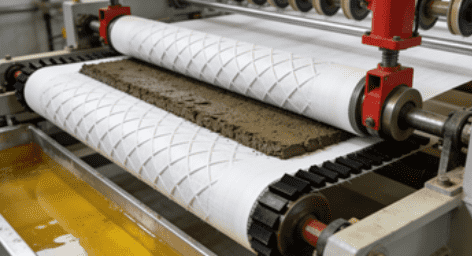

Belt Press Systems

Belt press units rely on gravity drainage followed by mechanical compression. They are suitable for large-capacity treatment, especially in municipal and industrial plants with stable sludge characteristics.

Screw Press Systems

Screw press equipment operates at low speed and low energy consumption. It is well suited for continuous operation, oily sludge, and projects that require minimal supervision and maintenance.

Centrifugal Dewatering Systems

Centrifuges use high rotational speed to separate solids and liquids. They are often selected for industrial sludge with fine particles or higher treatment demands.

Key Factors to Consider When Choosing a Dewatering Solution

Selecting the right dewatering system depends on multiple technical and operational factors, including:

- Sludge concentration and composition

- Required treatment capacity

- Target moisture content of the sludge cake

- Energy efficiency and automation level

- Installation space and plant layout

A professional equipment manufacturer can evaluate these factors and recommend a solution that matches actual operating conditions.

Dewatering Solutions for Different Industries

Municipal Wastewater Treatment Plants

Municipal facilities typically require stable, high-capacity systems capable of handling continuous sludge production while maintaining consistent performance.

Industrial Wastewater Treatment

Industrial sludge varies widely depending on the process involved. Customized designs are often necessary to manage oily, fibrous, or high-viscosity sludge effectively.

Challenging Sludge Conditions

For sludge with low solids content or poor dewaterability, optimized equipment structure and proper chemical conditioning are essential for reliable operation.

Cost and Operating Efficiency Considerations

When evaluating dewatering equipment, it is important to consider total lifecycle cost rather than initial investment alone.

| Cost Element | Impact on Operation |

|---|---|

| Equipment Investment | Influenced by capacity, materials, and automation |

| Energy Consumption | Determines long-term operating expenses |

| Maintenance Requirements | Affects downtime and spare parts costs |

| Sludge Disposal Savings | Reduced volume lowers transport and landfill fees |

An efficient and durable system can provide strong economic benefits throughout its service life.

Why Work with a Professional Manufacturer

Partnering with an experienced manufacturer ensures not only product quality but also long-term operational support. Key advantages include:

- Proven design and manufacturing expertise

- Custom-built equipment based on real sludge data

- Compliance with international standards

- Technical support, commissioning, and after-sales service

These factors are critical for ensuring stable operation and long-term reliability.

Customized Solutions for Your Project

Every wastewater treatment project has unique requirements. As a manufacturer, we provide tailored solutions based on:

- Sludge characteristics and treatment goals

- Integration with existing treatment systems

- Automation and control requirements

- OEM and export support for global projects

Customized engineering helps maximize efficiency and operational stability.

Common Dewatering Challenges and Practical Solutions

Low Separation Efficiency

Improper conditioning or unsuitable equipment selection is often the cause. Adjusting polymer dosing and process parameters can significantly improve results.

Equipment Wear and Blockage

Optimized structural design and proper material selection help reduce wear and extend service life.

High Operating Costs

Energy-efficient drives and automated control systems help minimize labor and power consumption.

How to Select the Right System for Your Project

A practical selection process includes:

- Sludge sampling and analysis

- Defining capacity and performance targets

- Comparing suitable dewatering technologies

- Evaluating supplier experience and support capabilities

An experienced manufacturer can guide you through each step and deliver a solution aligned with your project needs.

Conclusion

Effective sludge dewatering is essential for reducing waste volume, controlling operating costs, and improving wastewater treatment efficiency. By understanding different technologies, application scenarios, and cost factors, project owners can make informed decisions that deliver long-term value.

As a professional manufacturer of sludge treatment equipment, we focus on providing reliable, energy-efficient, and customized solutions for municipal and industrial wastewater projects worldwide. If you are planning a new project or upgrading an existing system, our team is ready to support you with practical engineering solutions and competitive pricing.

Contact us today to discuss your project and receive a customized dewatering solution.

FAQ

What is the main purpose of a sludge dewatering machine?

The main purpose is to remove excess water from sludge, reducing its volume and making handling, transportation, and disposal more efficient and cost-effective.

How do I choose the right sludge dewatering equipment for my project?

Selection depends on sludge characteristics, treatment capacity, moisture reduction requirements, and operating conditions. A professional manufacturer can recommend a suitable solution after analyzing your sludge data.

Which industries commonly use sludge dewatering systems?

These systems are widely used in municipal wastewater treatment, chemical processing, food production, pharmaceuticals, textiles, and other industrial wastewater applications.

What factors affect the operating cost of sludge dewatering equipment?

Key factors include energy consumption, polymer usage, maintenance requirements, and sludge disposal costs. Efficient design and automation can significantly reduce long-term expenses.

Can sludge dewatering solutions be customized for specific sludge conditions?

Yes. Equipment design can be customized based on sludge concentration, viscosity, oil content, and project layout to ensure stable performance and optimal dewatering efficiency.

Need Help Choosing the Right Sludge Dewatering Machine?

If you’re unsure which sludge dewatering solution is best for your wastewater treatment project, our experts are here to help. As an experienced manufacturer, we provide professional guidance and customized solutions based on your sludge conditions and operating requirements. Contact us today for a personalized consultation and ensure your sludge treatment process is efficient, reliable, and cost-effective. Don’t delay—get in touch now to optimize your wastewater treatment system!