Table of Contents

A 500 gallon grease trap is designed to handle large volumes of grease-laden wastewater generated by commercial kitchens. For restaurants, hotels, cafeterias, and industrial food service facilities, choosing the right grease trap capacity is essential for maintaining smooth operations, preventing sewer blockages, and complying with local plumbing codes.

As a professional 500 gallon grease trap manufacturer, we help commercial customers select reliable, durable, and code-compliant grease management solutions tailored to their specific needs.

What Is a 500 Gallon Grease Trap?

A 500 gallon grease trap is a high-capacity grease interceptor that separates fats, oils, and grease (FOG) from wastewater before it enters the municipal sewer system. By slowing down wastewater flow, grease rises to the surface while solids settle at the bottom, allowing cleaner water to exit the system.

This capacity level is commonly used in medium to large commercial kitchens where smaller grease traps are insufficient to handle daily wastewater output.

Applications of a 500 Gallon Grease Trap

A 500 gallon grease trap is widely used across various commercial and industrial food service environments, including:

- Restaurants with high daily meal volumes

- Hotel and resort kitchens

- School and hospital cafeterias

- Food courts and chain restaurants

- Industrial and central kitchens

These facilities generate consistent grease discharge, making a high-capacity grease trap essential for long-term performance and compliance.

Is a 500 Gallon Grease Trap Right for Your Facility?

Selecting the correct grease trap size depends on factors such as kitchen size, number of fixtures, and daily wastewater volume. A 500 gallon grease trap is typically recommended when:

- Multiple sinks, dishwashers, or floor drains are in use

- Daily food preparation volume is high

- Local codes require larger interceptors for commercial kitchens

Below is a simple comparison to help determine suitability:

| Interceptor Capacity | Typical Usage Level | Common Applications |

|---|---|---|

| Small (50–100 gal) | Light duty | Cafés, kiosks |

| Medium (250–300 gal) | Moderate volume | Small restaurants |

| Large (around 500 gal) | High volume | Restaurants, hotels |

| Extra-large (750+ gal) | Continuous discharge | Industrial kitchens |

Operational Benefits for Commercial Kitchens

Using a larger-capacity grease management system provides several long-term advantages:

- More effective separation under heavy wastewater flow

- Reduced likelihood of sewer line blockages

- Better alignment with municipal plumbing requirements

- Less frequent maintenance compared to smaller units

- Lower total cost of ownership over time

For growing food service businesses, these systems offer both reliability and scalability.

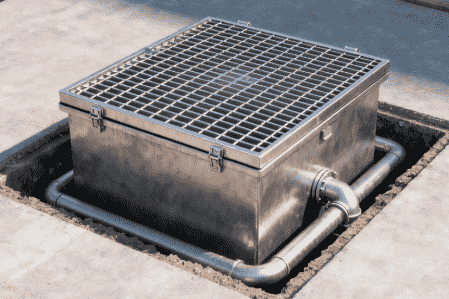

Design Features and Technical Characteristics

Commercial-grade grease interceptors are engineered with durability and efficiency in mind. Common design considerations include:

- Internal baffle configurations that improve separation efficiency

- Flow capacity suited for continuous commercial operation

- Reinforced construction for underground or indoor installation

- Flexible inlet and outlet positioning to match site conditions

As a manufacturer, we offer multiple construction materials, including HDPE, concrete, and stainless steel, to meet different environmental and structural requirements.

Underground and Indoor Installation Options

Depending on space availability and code requirements, grease interceptors can be installed either below ground or within the facility.

Underground systems are ideal for locations with limited interior space and higher discharge volumes, while indoor installations allow easier access for inspection and servicing. Our team evaluates each project individually to recommend the most practical configuration.

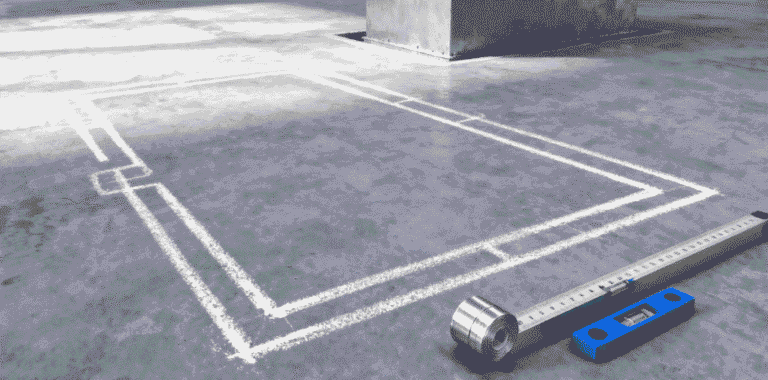

Installation Considerations and Code Compliance

Proper installation directly affects system performance and service life. Key factors include:

- Adequate excavation and base preparation for underground units

- Correct pipe alignment and venting

- Compliance with local plumbing and environmental standards

- Ensuring access points for routine maintenance

Working with a manufacturer who understands regulatory requirements helps avoid costly modifications later.

Maintenance and Long-Term Performance

Routine cleaning and inspection are essential for maintaining efficiency. Service frequency depends on usage intensity, but most high-volume kitchens benefit from scheduled maintenance every few months.

Regular upkeep helps prevent grease accumulation, reduces odor issues, and ensures continued compliance with local authorities. We provide guidance on maintenance intervals based on real-world operating conditions.

Why Work Directly With the Manufacturer

Choosing a manufacturer-direct supplier offers clear advantages for commercial projects:

- Consistent quality control throughout production

- Competitive pricing without intermediary markups

- Custom configurations for specific site requirements

- Products designed to meet recognized industry standards

- Technical support for contractors, engineers, and facility owners

Our solutions are used in a wide range of commercial and industrial food service environments worldwide.

How to Select and Order the Right System

Before placing an order, it is helpful to gather basic project information such as kitchen layout, fixture count, installation location, and local code requirements. Our engineering team works closely with customers to recommend the most suitable configuration, whether standard or customized.

We support bulk orders, OEM projects, and long-term supply partnerships.

Conclusion

For commercial kitchens handling significant wastewater volumes, a properly sized grease interception system is essential for operational efficiency and regulatory compliance. Selecting the right capacity and working with an experienced manufacturer can significantly reduce maintenance issues and long-term costs.

As a professional manufacturer of commercial grease management solutions, we provide durable, compliant, and customizable systems for restaurants, hotels, cafeterias, and industrial kitchens. From initial consultation to final delivery, our team is committed to supporting your project with reliable expertise.

Contact us today to discuss your application and receive professional guidance on selecting the right grease management solution for your facility.

FAQ

What is a 500 gallon grease trap used for?

It is used in commercial kitchens to separate fats, oils, and grease from wastewater before it enters the sewer system, helping prevent blockages and meet plumbing regulations.

Is a 500 gallon grease trap suitable for restaurants?

Yes. This capacity is commonly used in medium to large restaurants, hotels, and cafeterias with high daily wastewater output.

How often should a 500 gallon grease trap be cleaned?

Cleaning frequency depends on usage, but most commercial kitchens require servicing every 1 to 3 months to maintain proper performance.

Can a 500 gallon grease trap be installed underground?

Yes. Many high-capacity grease traps are designed for underground installation, especially when indoor space is limited or local codes require external placement.

How do I choose the right grease trap size for my kitchen?

Grease trap sizing depends on fixture count, kitchen layout, operating hours, and local plumbing codes. Consulting a manufacturer helps ensure proper selection.

Need Help Choosing the Right Grease Trap Capacity?

If you’re unsure which grease management solution is best for your commercial kitchen, our experts are here to help. Contact us today for a personalized consultation, and get a high-quality, code-compliant grease trap designed for your specific application. Don’t risk costly plumbing issues—reach out now and ensure long-term performance and compliance for your facility!