Table of Contents

Choosing the right water treatment equipment manufacturers is a critical decision for industrial plants, municipal projects, and commercial facilities. Reliable water treatment equipment manufacturers not only supply equipment, but also provide system design, engineering support, and long-term technical service.

As a professional water treatment equipment manufacturer, we help global customers source high-quality systems directly from a certified water treatment equipment factory. This buyer’s guide explains how water treatment equipment manufacturers operate, what products they offer, and why working directly with a manufacturer is the best choice for cost-effective and customized water treatment solutions.

What Do Water Treatment Equipment Manufacturers Do?

Water treatment equipment manufacturers are responsible for the design, engineering, production, and testing of water treatment systems. A professional water treatment equipment manufacturer manages the entire manufacturing process, from raw material selection to final system inspection.

Unlike trading companies, experienced water treatment equipment manufacturers focus on system performance, reliability, and compliance with international standards. Choosing the right water treatment equipment manufacturer ensures stable operation and long service life.

Manufacturers vs Suppliers vs Distributors

Water treatment equipment manufacturers design and build systems in their own factories, while suppliers and distributors mainly resell standard products. Working directly with water treatment equipment manufacturers gives buyers better pricing, faster communication, and full engineering support.

Why Buying Directly from a Manufacturer Matters

Buying directly from water treatment equipment manufacturers allows customers to request custom designs, OEM solutions, and factory-level quality control. This approach reduces project risk and improves overall system efficiency.

Types of Water Treatment Equipment Manufactured

Professional water treatment equipment manufacturers produce a wide range of systems for different applications and water sources.

Drinking Water Treatment Equipment

These systems are designed to remove impurities, bacteria, and harmful substances to meet potable water standards. They are widely used in municipal and community water projects.

Industrial Water Treatment Systems

Industrial systems are customized to support manufacturing processes, boiler feed water, cooling systems, and process water reuse.

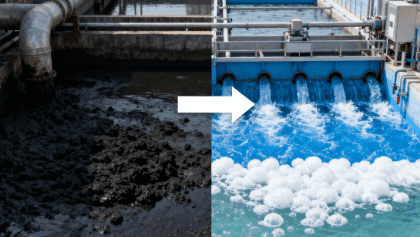

Wastewater Treatment Equipment

Wastewater treatment equipment helps industries and municipalities treat effluent before discharge or reuse, ensuring compliance with environmental regulations.

RO, UF, and Membrane-Based Systems

Advanced membrane technologies such as reverse osmosis (RO) and ultrafiltration (UF) are commonly manufactured for high-purity and water reuse applications.

Industrial Applications Served by Water Treatment Equipment Manufacturers

Water treatment equipment is used across multiple industries where water quality and system reliability are critical.

Manufacturing and Processing Industries

Industries such as food & beverage, electronics, chemicals, and textiles rely on stable water quality to protect production processes and equipment.

Power Plants and Energy Facilities

Power generation facilities require precise water treatment solutions for boilers, cooling systems, and wastewater management.

Municipal and Public Water Projects

Municipal projects depend on durable, large-capacity systems designed for continuous operation and regulatory compliance.

Commercial Buildings and Infrastructure

Hotels, hospitals, data centers, and commercial complexes use water treatment systems to ensure safe and efficient water use.

How to Choose a Reliable Water Treatment Equipment Manufacturer

Selecting the right manufacturer involves more than comparing prices. Buyers should evaluate technical capability, manufacturing standards, and long-term service support.

Manufacturing Experience and Technical Expertise

Experienced manufacturers understand different water conditions and can design systems that perform reliably in real-world applications.

Certifications and Quality Standards

International certifications such as ISO and CE indicate standardized production processes and quality assurance.

Customization and Engineering Capability

Every project has unique requirements. A capable manufacturer can provide customized designs rather than one-size-fits-all solutions.

After-Sales Support and Technical Service

Reliable after-sales support ensures stable system operation and minimizes downtime throughout the equipment’s lifecycle.

Benefits of Working Directly with Water Treatment Equipment Manufacturers

Working directly with a manufacturer offers clear advantages for B2B buyers and project owners.

Cost Efficiency and Factory Pricing

Direct factory supply eliminates unnecessary intermediaries, allowing buyers to benefit from competitive pricing.

Custom Design for Specific Water Conditions

Manufacturers can adjust system design based on raw water quality, treatment goals, and site conditions.

Better Quality Control and Lead Time

In-house production ensures consistent quality control and predictable delivery schedules.

Long-Term Technical Support

Manufacturers provide ongoing technical guidance, spare parts support, and system optimization.

Custom Water Treatment Solutions for Global Projects

As global water challenges increase, manufacturers play a vital role in delivering customized solutions for international projects.

OEM and Private Label Manufacturing

Many manufacturers offer OEM and private label services, enabling partners to build their own brands with reliable technical support.

Turnkey Water Treatment System Solutions

Turnkey solutions cover design, manufacturing, testing, and commissioning, simplifying project execution.

Export Experience and International Compliance

Experienced manufacturers understand export requirements and international standards, ensuring smooth global delivery.

Case-Based Engineering Design

System designs are often based on real project data and proven engineering practices.

Quality Control and Manufacturing Process

A professional water treatment equipment manufacturer follows strict quality control procedures throughout production.

Raw Material Selection and Component Testing

Only qualified materials and components are used to ensure long-term system reliability.

Production, Assembly, and System Integration

Each system is carefully assembled and integrated to match the approved engineering design.

Factory Testing and Performance Inspection

Before delivery, systems undergo functional and performance testing to verify treatment efficiency.

Packaging and Global Shipping Standards

Proper packaging protects equipment during international transportation and installation.

Cost Factors and Pricing of Water Treatment Equipment

The cost of water treatment equipment depends on multiple technical and project-related factors.

| Cost Factor | Description |

|---|---|

| Treatment Capacity | Higher flow rates require larger systems and components |

| Water Quality | Complex raw water conditions increase system complexity |

| System Configuration | RO, UF, or multi-stage systems affect overall cost |

| Customization Level | Fully customized designs may cost more than standard units |

| Materials & Components | Choice of materials impacts durability and price |

Understanding these factors helps buyers evaluate quotations more accurately and avoid unexpected costs.

Why Choose Us as Your Water Treatment Equipment Manufacturer

As a professional water treatment equipment manufacturer, we provide complete in-house solutions from design to delivery.

In-House Manufacturing and Engineering Team

Our engineering team designs systems tailored to each project’s technical requirements.

Proven Experience in Industrial and Municipal Projects

We have supplied water treatment equipment for diverse applications worldwide.

Customized Solutions with Fast Delivery

Efficient production processes allow us to deliver high-quality customized systems on time.

Dedicated Technical Support and Global Service

We support our clients throughout the entire project lifecycle, from installation to long-term operation.

Frequently Asked Questions About Water Treatment Equipment Manufacturers

How long is the production lead time?

Production time depends on system complexity and customization level, typically ranging from a few weeks to several months.

Can manufacturers provide customized systems?

Yes, professional manufacturers design systems based on specific water conditions and project needs.

Do you offer installation and technical support?

Manufacturers often provide remote or on-site technical support, depending on project requirements.

What certifications do your products have?

Most professional manufacturers comply with international quality and safety standards.

Conclusion

Choosing the right water treatment equipment manufacturer is essential for achieving reliable performance, regulatory compliance, and long-term cost efficiency. By working directly with an experienced manufacturer, buyers gain access to customized solutions, strict quality control, factory-direct pricing, and continuous technical support.

As a professional water treatment equipment manufacturer, we are committed to delivering efficient, durable, and customized systems for industrial, municipal, and commercial applications. If you are looking for a reliable manufacturing partner for your next water treatment project, working directly with a trusted manufacturer makes all the difference.

Need Help Choosing the Right Water Treatment Equipment?

If you’re unsure which water treatment system is best for your industrial, municipal, or commercial project, our experts are here to help. As a professional water treatment equipment manufacturer, we provide customized solutions tailored to your water quality requirements and application needs. Contact us today for a personalized consultation and get reliable, cost-effective water treatment equipment designed for long-term performance. Don’t compromise on water quality—get in touch with us now and start your project with confidence.