Welcome to My Blog! 🌟

I’m so glad you’re here! Before we jump into the exciting content, I’d love for you to connect with me on my social media platforms. It’s where I share extra insights, interact with our amazing community, and post regular updates. Here’s how you can join the conversation:

📘 Facebook: Follow me on Facebook for more updates

Now, let’s dive into the journey ahead. I hope you find everything here both engaging and valuable. Together, let’s explore, learn, and grow! 🚀

Table of Contents

Introduction

Ensuring compliance with Industrial Incinerator laws is not only a legal requirement but also a critical component of corporate environmental responsibility. As Industrial Incinerator operators and users face increasingly stringent regulations worldwide, understanding the legal landscape becomes essential. In this blog, we explore key aspects of Industrial Incinerator legislation, sustainable development concerns raised by international stakeholders, and practical guidance on maintaining full compliance. Along the way, we introduce Shandong Lushun Environmental Technology Co., Ltd. and its state‑of‑the‑art Industrial Incinerator solutions designed to help you meet and exceed regulatory standards.

What Is an Industrial Incinerator?

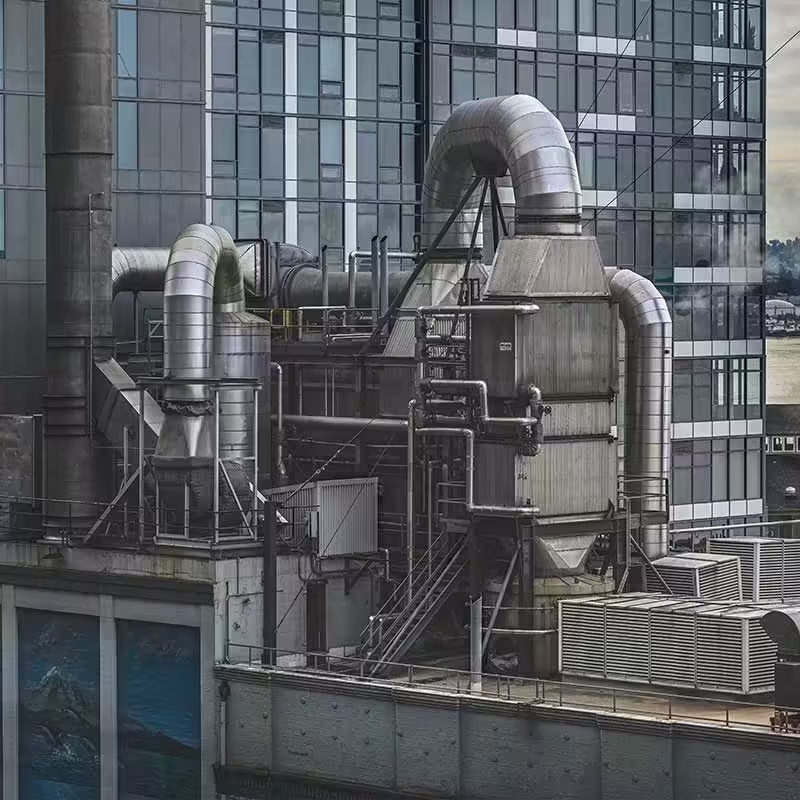

Industrial Incinerator refers to a thermal oxidation unit designed to process industrial waste—ranging from chemical by‑products to organic refuse—at temperatures between 800℃ and 1200℃. Through controlled combustion, Industrial Incinerator systems convert waste into heat energy, flue gas, and solid residues while minimizing harmful emissions. Properly engineered Industrial Incinerator technology ensures complete oxidation of organic constituents, reducing pollutants and facilitating energy recovery.

Principle of Thermal Oxidation in Industrial Incinerator

Industrial Incinerator systems rely on three core parameters: temperature, air supply (wind), and residence time. By maintaining high temperatures (800℃–1200℃), adjusting primary and secondary airflows, and controlling the duration that waste remains in the combustion chamber, Industrial Incinerator units achieve high destruction efficiencies. This precise control mitigates the release of dioxins, furans, and other hazardous compounds.

Key Components

- Combustion Chamber: The main furnace where waste is oxidized.

- Heat Recovery System: Captures thermal energy for reuse, improving overall energy efficiency.

- Flue Gas Treatment: Employs filters, scrubbers, and catalytic units to remove particulates and gaseous pollutants.

- Control System: Automates monitoring of temperature, airflow, and emissions to ensure stable operation.

Understanding Industrial Incinerator Laws

Around the world, government agencies and environmental organizations have enacted increasingly stringent regulations to safeguard public health and the ecosystem. Facilities involved in industrial-scale waste combustion must adhere to comprehensive legal frameworks. These include strict emission standards, licensing procedures, and meticulous documentation of daily operations. Falling short of these obligations can result in significant penalties, reputational damage, and operational shutdowns.

Major Regulatory Frameworks

Regulatory expectations vary by region, but all aim to control pollution, protect air quality, and ensure safe waste disposal. Below are key regulatory systems shaping the compliance landscape:

European Union: The Industrial Emissions Directive (IED) is one of the most robust environmental laws in the EU. It outlines mandatory thresholds for pollutants such as nitrogen oxides (NOₓ), sulfur dioxide (SO₂), and suspended particulate matter. Waste treatment facilities must operate within these boundaries, employing modern technology to limit atmospheric contamination.

United States: American waste incineration facilities fall under the jurisdiction of the U.S. Environmental Protection Agency (EPA). Two crucial programs govern operations: the New Source Performance Standards (NSPS), which set performance benchmarks for new units, and the National Emission Standards for Hazardous Air Pollutants (NESHAP), designed to curb hazardous outputs from existing installations.

China: In China, waste combustion practices are guided by national standards formulated by the Ministry of Ecology and Environment (MEE). Among these, the GB 18485‑2014 standard—originally drafted for municipal solid waste incinerators—has been extended to apply to many industrial combustion applications, particularly those involving organic or hazardous by-products.

Key Regulations

Authorities across all jurisdictions share similar concerns over certain classes of emissions, many of which are known to have adverse environmental and health effects. To remain compliant, waste treatment plants must invest in cutting-edge emission control technologies.

- Dioxins and Furans: These highly toxic compounds are subject to maximum allowable concentrations, often capped at 0.1 nanograms TEQ per cubic meter. Achieving such low levels demands advanced gas cleaning systems, including activated carbon filters and catalytic reactors.

- Heavy Metals: Elements such as mercury, cadmium, and lead are strictly regulated. Emissions must generally remain below 0.05–0.5 milligrams per cubic meter depending on local rules. Multi-stage filtration, gas cooling, and sorbent injection are common methods used to manage these substances.

- Acidic Compounds: Gases like SO₂ and hydrogen chloride (HCl) form as a result of material decomposition under high heat. Both dry and wet scrubbing systems are used to neutralize these corrosive elements before they reach the atmosphere.

- Particulates: Tiny airborne solids released during combustion can pose serious respiratory risks. Legal limits usually fall between 10 and 30 mg/Nm³. Operators deploy technologies such as baghouse filters or electrostatic precipitators to achieve compliance.

Corporate Responsibility and Sustainable Development

In addition to legal compliance, international stakeholders increasingly expect companies operating Industrial Incinerator facilities to demonstrate sustainable development practices. Common concerns include carbon footprint reduction, energy recovery utilization, and transparent reporting.

Integrating Circular Economy Principles with Industrial Incinerator

A circular economy approach emphasizes resource efficiency and waste minimization. By integrating Industrial Incinerator units equipped with heat recovery boilers and co‑generation systems, companies can convert waste-derived thermal energy into electricity or process steam, thereby reducing overall greenhouse gas emissions.

Addressing International Sustainability Concerns

- Carbon Emission Accounting: Many multinational customers request detailed carbon accounting reports for waste treatment processes, including CO₂e per ton of waste incinerated.

- Renewable Energy Credits: Utilizing surplus energy from Industrial Incinerator systems may qualify for renewable energy certificates in certain markets.

- Community Engagement: Transparent public disclosure of emission data and community health impact assessments fosters trust and social license to operate.

Table: Typical Industrial Incinerator Technical Specifications

Below is a comparison of key parameters for a standard Industrial Incinerator model offered by Shandong Lushun Environmental Technology Co., Ltd. This table illustrates how design choices affect performance, compliance, and sustainability metrics.

| Parameter | Unit | Model LS‑II800 | Model LS‑II1000 | Model LS‑II1200 |

|---|---|---|---|---|

| Operating Temperature | ℃ | 800–900 | 900–1000 | 1000–1200 |

| Throughput Capacity | Tons/day | 5–10 | 10–20 | 20–30 |

| Residence Time | Seconds | 1.5–2.0 | 1.2–1.8 | 1.0–1.5 |

| NOₓ Emission Limit | mg/Nm³ | ≤200 | ≤180 | ≤150 |

| Dioxin Emission Limit | ng TEQ/Nm³ | ≤0.1 | ≤0.1 | ≤0.1 |

| Energy Recovery Efficiency | % | 25–30 | 30–35 | 35–40 |

| Flue Gas Treatment | – | Baghouse + Scrubber | Baghouse + Scrubber | Baghouse + SCR + Scrubber |

Advantages of Shandong Lushun’s Industrial Incinerator Solutions

Shandong Lushun Environmental Technology Co., Ltd. is an environmental protection professional technology enterprise committed to innovation, manufacturing excellence, and comprehensive service. By choosing our Industrial Incinerator products, you benefit from:

- Advanced Technology: Incorporating foreign advanced techniques with ongoing in‑house improvement.

- High‑Quality Manufacturing: Robust fabrication processes ensure long service life and stable performance.

- Integrated Supply Chain: One‑stop procurement of environmental protection products, reducing project lead times.

- Technical Support and Services: Full lifecycle support including installation, commissioning, operator training, and maintenance.

Company Overview in the Context

Shandong Lushun Environmental Technology Co., Ltd. integrates environmental protection technology innovation with equipment manufacturing and product supply. Our flagship Industrial Incinerator line exemplifies this synergy, offering pyrolysis of industrial waste at 800℃–1200℃, complete combustion control, and optimized flue gas cleaning to meet or exceed global emission standards.

Best Practices for Industrial Incinerator Operation and Maintenance

Maintaining compliance requires not only proper installation but vigilant operation and regular maintenance of Industrial Incinerator units. Best practices include:

- Routine Emission Monitoring: Continuous Emission Monitoring Systems (CEMS) for real‑time data on NOₓ, SO₂, CO, and particulate levels.

- Periodic Inspection and Calibration: Annual checks of burners, fans, and sensors to ensure accurate temperature and airflow control.

- Scheduled Maintenance: Timely replacement of filter bags, catalyst layers, and refractory bricks to preserve system integrity.

- Operator Training: Comprehensive training programs on emergency shutdown, startup procedures, and regulatory reporting requirements.

Leveraging Digital Solutions for Compliance

Modern Industrial Incinerator installations increasingly deploy SCADA systems and Industrial Internet of Things (IIoT) sensors. These technologies facilitate predictive maintenance, automated reporting to regulatory agencies, and remote performance optimization.

Sustainable Procurement and Lifecycle Impact

Beyond the operational phase, companies must consider the full lifecycle impact of their Industrial Incinerator systems—from raw material sourcing to end‑of‑life decommissioning.

Eco‑Design Principles for Industrial Incinerator Equipment

- Material Selection: Utilizing recycled steel and low‑emission welding materials to reduce embodied carbon.

- Modular Construction: Designing incinerator sections for easier future upgrades and retrofits, extending service life.

- End‑of‑Life Recycling: Planning for dismantling and recycling of metal components to minimize waste.

Conclusion

Ensuring compliance with Industrial Incinerator laws is a multidimensional undertaking—encompassing legal, technical, and sustainability considerations. By understanding regulatory frameworks, adopting advanced technologies, and partnering with a trusted provider like Shandong Lushun Environmental Technology Co., Ltd., organizations can achieve efficient waste disposal, energy recovery, and minimal environmental impact.

FAQ

What permits are required for operating an Industrial Incinerator?

Permit requirements vary by jurisdiction. Commonly, operators must secure an Air Emissions Permit, an Industrial Waste Permit, and local environmental approvals. Shandong Lushun’s project team can assist with permit applications.

How often should emission testing be conducted?

Continuous monitoring is recommended for key pollutants, with periodic stack testing (e.g., quarterly or annually) to validate CEMS data. Consult local regulations for exact frequencies.

Can Industrial Incinerator systems be used for biomass or municipal waste?

While primarily designed for industrial waste, certain models can process biomass and municipal refuse with appropriate feedstock preparation and permit amendments.

What measures reduce the carbon footprint of Industrial Incinerator operations?

Implementing energy recovery, optimizing combustion efficiency, and integrating renewable energy credits all help lower net CO₂e emissions. Lifecycle assessments can quantify improvements.

How does International sustainability reporting impact Industrial Incinerator operators?

Global frameworks such as the GRI Standards and CDP encourage disclosure of emissions data, energy use, and waste management practices. Operators should align data collection with these standards.