Choosing the right pet incinerator is about more than picking a machine: it’s a decision that affects public health, environmental compliance, service quality, and the dignity you return to grieving owners. Whether you run a veterinary clinic, animal shelter, municipal animal services department, or a dedicated pet crematorium, the right system reduces liability, simplifies workflows, and can even become a service-line revenue generator. This expanded guide turns technical data, regulations, and real-world price points into practical buying steps you can act on today.

Table of Contents

Key Takeaways from This Guide

- Understand what a pet incinerator is and how it works

- Learn the regulatory and environmental considerations you cannot ignore

- See real-world capacity and performance ranges for different models

- Get concrete price ranges and cost drivers — how much does a pet incinerator cost?

- Compare incineration vs burial and outsourcing with data-backed pros/cons

- Operational, installation, and lifecycle maintenance checklists for buyers

- A practical FAQ that reflects how people actually ask questions today

What Is a Pet Incinerator (Concise Concept)

A pet incinerator is a thermal disposal system designed to reduce animal remains to sterile ash through high-temperature combustion and controlled flue-gas treatment. Built for dignified, hygienic disposal, these units combine combustion chambers, temperature control, ash handling, and exhaust treatment to meet safety and emission standards.

Core components (short descriptions)

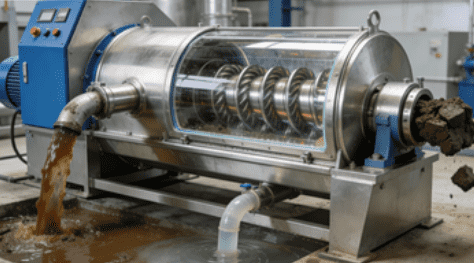

- Feeding mechanism: Automated or manual system that introduces carcasses into the chamber.

Ensures safe operator interaction and consistent loading. - Combustion chamber + burner: The heart of the system that achieves and sustains high temperatures needed for complete oxidation.

Proper burner sizing affects cycle time and fuel consumption. - Flue gas purification: Filters and scrubbers (or catalytic systems) that reduce particulates, dioxins, furans, and acid gases before release.

Critical for meeting local emissions rules. - Ash collection & cooling: Systems designed for dignified ash handling and, when required, return of ashes to owners.

How a Pet Incinerator Works — Step-by-Step (Concept Blocks)

1. Loading / Feeding

Automated feeding reduces operator exposure; different designs support single-animal loads or batch processing. Small units commonly accept single companion animals; commercial units accept multiple or large animals.

2. Controlled Combustion

High-temperature combustion (often 800–1,100°C for small-scale cremation; higher for some industrial systems) ensures destruction of pathogens and breakdown of organic material. Real-time control systems maintain the required temperature profile.

3. Flue Gas Treatment

After combustion, exhaust passes through purification systems (cyclones, filters, scrubbers, or catalysts) to meet particulate and toxic emission limits. Meeting regulatory thresholds is non-negotiable for most jurisdictions.

4. Ash Handling & Disposal

After combustion, the remaining ash is cooled and collected. Many pet incinerator systems are designed to allow respectful ash handling or return to pet owners.

Regulatory & Environmental Landscape (Must-Know)

Emission standards and permits

Incinerators are subject to federal and local rules for particulate matter, acid gases, heavy metals, dioxins/furans, and other hazardous combustion by-products. For example, EPA guidance and rulemaking documents explicitly address incinerator controls and emission limits relevant to medical and animal waste disposal. Proper permits and compliance monitoring are required.

Best available techniques and monitoring

Authoritative reviews (e.g., government and technical assessments) recommend robust flue gas treatment and temperature monitoring as best practices, especially for small-scale carcass incinerators where emissions variability is greater. Routine stack testing and continuous temperature/combustion monitoring are commonly expected.

International perspectives

European and national agencies study impacts of incineration on animal by-product safety (e.g., EFSA assessments) and routinely publish guidance for Category 1/2/3 carcass disposal, which influences equipment specs in many markets.

Real-World Capacity & Performance Ranges (Data-Oriented)

To match equipment to need, consider typical capacity bands and what they mean in practice:

Small/Companion Units

- Load size: typically up to 50–90 kg (110–200 lbs) per batch.

- Incineration rate: ~20–50 lbs/hour (9–22 kg/hr) on some models.

- Use cases: single-clinic onsite cremation, low-volume shelters.

Medium Commercial Units

- Load size: up to several hundred kg per load.

- Incineration rates: 100–500 kg/hr depending on design.

- Use cases: small crematoriums, larger shelters, municipal centers.

High-Volume / Industrial

- Load size & rate: several hundred to thousands of kg capacity with 500+ kg/hr burn rates in industrial designs.

- Use cases: centralized carcass disposal centers, large-scale rendering or high-throughput cremation services.

Practical note: match the average daily throughput (number of animals/day) rather than peak-load only; oversizing increases capital and fuel cost, undersizing creates queues and operational headaches.

How Much Does a Pet Incinerator Cost?

One of the most common buyer questions is: how much does a pet incinerator cost?

The price of a pet incinerator varies widely depending on capacity, automation level, emission control configuration, and installation requirements.

Typical price ranges (industry data)

- Small/companion cremator: from roughly $3,000 – $25,000 for lightweight or entry-level units.

- Mid-range commercial units: typically $20,000 – $120,000 depending on automation and emission controls.

- Full-scale crematory systems / high-capacity incinerators: $120,000 – $500,000+ for turnkey, high-throughput installations including advanced flue gas treatment, installation, and auxiliary systems. Examples cited show full-scale units quoted near $220,000 for comprehensive systems.

Other up-front and recurring costs

Automation and Ease of Use

Automated pet incinerators reduce labor requirements and improve safety. Features like automatic ignition and ash discharge simplify daily operation.

Space and Installation Requirements

Each pet incinerator has specific footprint and installation needs. Buyers must consider machine dimensions, weight, and access for delivery and maintenance.

Return-on-investment considerations

Facilities that charge cremation fees (e.g., $100–$400 per cremation depending on service) can often recover capital costs over a number of years — but realistic ROI must account for operating cost, utilization rate, and local demand. Industry case analyses show payback scenarios are highly sensitive to per-session throughput and service pricing.

Key Purchase Criteria — A Checklist for Buyers

Use this checklist during vendor selection and procurement.

1) Compliance & Certification

- Confirm the unit is designed to meet applicable national and local emissions and waste regulations. Request vendor documentation of emission controls and any third-party stack test results.

2) Throughput vs Actual Demand

- Calculate average daily and peak needs. Ask vendors for cycle times and per-hour incineration rates for the model under expected loads.

3) Fuel Type & Efficiency

- Gas burners (natural gas/propane) are common; some industrial designs use fuel oil or dual burners. Confirm fuel availability and estimate cost per session. Energy efficiency specifications materially affect operating cost.

4) Emission Controls & Monitoring

- Verify presence and performance of flue gas purification (filters, scrubbers) plus continuous monitoring options. Request documentation or third-party test results.

5) Automation & Operator Safety

- Automated feeding, ignition, and ash handling reduce labor and risk. Confirm operator interface, safety interlocks, and training support.

6) Service, Warranty & Spare Parts Availability

- For long-term operation, timely service and parts availability are crucial. Check for factory service centers or authorized distributors in your region.

7) Footprint & Installation Constraints

- Confirm machine and packaging dimensions, lifting and access needs, and utility requirements. The sample machine dimensions you provided (e.g., 5200mm × 1600mm × 2600mm; weight 5200 kg) match medium-to-large units and require heavy-duty installation planning.

Comparative Tables (Quick Visual Decision Aids)

Comparison: Small vs Medium vs Large Systems (high-level)

| Feature | Small Unit | Medium Commercial | Large/Industrial |

|---|---|---|---|

| Typical load | up to 50–200 lbs | up to several hundred kg | up to thousands kg |

| Typical cost | $3k–$25k | $20k–$120k | $120k–$500k+ |

| Throughput | low (1–4/day) | moderate (10s/day) | high (100s/day) |

| Emission controls | basic | advanced | full industrial scrubbers |

| Best for | Vet clinics, single-site | Crematoriums, shelters | Municipal or centralized facilities |

(Data ranges pulled from available market examples and vendor specs.)

Case Studies & Real-World Examples

Municipal Carcass Centre — A Recent Example

A municipal facility in India opened a modern carcass center equipped with dual incinerators: a large unit capable of ~300 kg/hour and a small unit at ~50 kg/hour. The project cost was ₹1.79 crore and included environmental scrutiny plus a five-year maintenance contract — illustrating how public projects specify capacity and service guarantees to ensure compliance and community acceptance.

Small Clinic ROI Example

A small clinic using a compact unit priced at roughly $21,700 (unit price example from multiple vendors) calculated operating costs and revenue (charging cremation fees). Assumptions around utilization (e.g., 1 cremation/day vs higher volumes) dramatically change payback time. Industry vendors publish sample payoff calculations illustrating that higher utilization materially improves ROI.

Design & Technical Deep Dive (For Technical Buyers)

Chamber materials and refractory

High-quality incinerators use refractory linings and stainless steel inner jackets to withstand thermal cycling. Select materials rated for consistent service at the operating temperature you require.

Burner control & PID loops

Modern systems use PID control loops to keep combustion within tight tolerances. This stabilizes temperature, reduces incomplete combustion, and lowers emissions.

Stack design and dispersion modeling

Stack height, exit velocity, and site-specific dispersion modeling (sometimes required for permits) influence whether a unit will meet local air quality limits. Most permitting authorities require stack testing and dispersion assessments for new installations.

Operations & Maintenance — Practical Guidance

Daily checklist (short bullets)

- Pre-start safety and leak checks

- Confirm fuel and utility availability

- Verify combustion temperature setpoint and monitoring systems

- Record cycle start/stop times and any alarms

Routine maintenance (monthly/quarterly)

- Inspect refractory for cracks

- Clean/replace filters in flue gas systems

- Lubricate mechanical feeders and check seals

- Schedule annual stack testing as required by permits

Spare parts you should stock

- Burner nozzles and igniters

- Temperature sensors (thermocouples)

- Control relays and fuses

- Flue filter elements or catalyst modules

Health, Safety & Biosecurity Considerations

- Use fully enclosed systems to prevent exposure to pathogens and odors.

- Ensure staff training in safe loading and ash handling procedures.

- For euthanized animals or animals with transmissible diseases, follow local guidance on special handling and decontamination before incineration. Government guidance and veterinary practice standards often prescribe segregation and documentation.

Vendor Selection: RFP / Tender Template (Brief)

When preparing to request quotes, include:

- Expected daily and peak throughput (avg animals/day; largest animal size)

- Required emission compliance level & permit references

- Site constraints (footprint, stack height limits, fuel availability)

- Warranty, service response time, and spare parts policy

- Training and documentation deliverables

- Estimated project timeline including commissioning and stack testing

Common Buyer Mistakes & How to Avoid Them

Mistake: Purchasing by price alone

Cheaper units may lack adequate emission controls and suffer higher operating costs. Evaluate total cost of ownership (TCO) — capital + installation + fuel + maintenance + compliance.

Mistake: Undersizing the unit

This creates backlog, staff overtime, and could force offsite disposal. Use realistic demand data and plan for modest growth.

Mistake: Ignoring local permitting realities

Permits can be lengthy and may require additional emission controls or operational restrictions. Engage environmental consultants early.

Expert Perspectives (Paraphrased & Cited)

- Regulatory authorities and guidance: EPA and regulatory documents emphasize particulate and hazardous combustion by-product controls; facilities should plan for stack testing and continuous monitoring to comply with modern standards.

- Technical reviews (UK / DEFRA style): Small incinerators display higher emissions variability; best available techniques recommend robust combustion control and flue gas treatment tailored to each installation.

- Industry vendors and case studies: Vendor data show broad price and capacity ranges, highlighting the need to match unit specs to workload rather than defaulting to a single “popular” model. Multiple vendor examples show that small units can be economical for clinics, while crematoria and municipal centers require industrial designs.

Advanced Topics — For Buyers Who Want to Go Deeper

Thermal efficiency metrics

Understand energy per kg of carcass processed and how insulation, burner design, and heat recovery affect fuel consumption.

Heat recovery & sustainability

Some designs allow for waste heat recovery for facility heating or pre-heating combustion air, improving operating economics and lowering carbon footprint.

Lifecycle analysis & circularity

Consider a lifecycle approach: manufacturing footprint, transport emissions (heavy machines have high shipping impacts), operational emissions, and end-of-life disposal for refractory materials.

Final Buying Roadmap — 8 Practical Steps

- Quantify demand — realistic daily and peak needs.

- Define compliance targets — confirm local permit limits and testing obligations.

- Set a TCO budget — include installation, running costs, and permit costs.

- Shortlist vendors — require specs, third-party test results, and references.

- Visit installations — inspect similar installations in operation if possible.

- Plan site & logistics — stack location, utilities, lifting equipment, and ash return process.

- Negotiate warranty & service — include response times and spare parts agreements.

- Train staff & document SOPs — safe operation, maintenance, and recordkeeping.

Appendix: Helpful Reference Links & Documents (Select Sources Cited Above)

- EPA regulatory and guidance materials on incinerator emissions and standards.

- UK DEFRA / technical reviews of small carcass incinerator emissions and BAT recommendations.

- Market and vendor cost references showing typical price ranges and examples of small/large systems.

- Vendor capacity and specification examples (rates, load sizes) for small to industrial systems.

- Recent municipal implementation example (case from Chandigarh) showing how modern carcass centers are sited and commissioned.

Closing Thought

Buying a pet incinerator is a technical procurement wrapped in an ethical service promise. Get the right spec, document compliance, and you not only solve a practical disposal need — you provide a respectful, professional end-of-life option that supports staff safety and community standards. If you want, I can now: generate an RFP template customized to your jurisdiction; produce a side-by-side model comparison (based on your expected throughput); or draft sample permit language to share with local environmental authorities. Which would help most next?

FAQ

How much does a pet incinerator cost and what affects the price?

Costs vary widely: small units can start in the low thousands, mid-range commercial systems often fall in the tens of thousands, and full-scale crematorium installations can exceed $200,000. Major price drivers are capacity, emission control equipment, automation, site preparation, and permitting.

How long does a pet incinerator cycle take?

Cycle time depends on load size and pet incinerator capacity, typically optimized for daily operational efficiency.

Can a vet clinic legally run a pet incinerator on site?

Often yes, but it depends on local air quality permits and zoning. Clinics must meet emissions standards and obtain any required permits from local environmental agencies. Early engagement with regulators is essential.

Is cremation better than burial for the environment?

Incineration eliminates risks of soil contamination and pathogen persistence that can accompany burial. However, incineration produces emissions that must be controlled; with modern flue gas treatment, environmental impact can be minimized. The “better” option depends on local conditions and regulatory context.

Does a pet incinerator require special permits?

In most regions, operating a pet incinerator requires environmental permits and compliance documentation.

Can ashes from a pet incinerator be returned to owners?

Yes, many pet incinerator systems support respectful ash collection and return.

What are the ongoing costs per cremation?

Ongoing costs include fuel, electricity, labor, maintenance, and eventual spare parts. Case examples estimate per-session fuel costs (e.g., $20–$40 for small sessions) plus labor and consumables; real numbers depend on local fuel prices and utilization.