Sludge dewatering is a critical step in modern wastewater and industrial waste management. By reducing water content, facilities can reduce disposal costs, optimize transport, enhance energy recovery, and comply with environmental regulations.

Dewatering sludge technologies range from mechanical systems such as centrifuges and belt presses to chemical and thermal methods. This article explores each technology, including operational concepts, comparative advantages, applications, cost analysis, and industry insights.

Table of Contents

Key Takeaways

- Dewatering sludge reduces water content, lowers disposal costs, and improves environmental compliance.

- Key technologies include centrifuges, belt presses, screw presses, and filter presses, each with distinct advantages.

- Understanding process efficiency, chemical conditioning, cost, and operational requirements is essential for technology selection.

- Comparative frameworks assist decision-makers in selecting mechanical, chemical, or thermal solutions.

- Industry data supports adoption, and expert insights highlight best practices for modern facilities.

Understanding Dewatering Sludge

The Concept of Sludge Dewatering

Sludge dewatering removes water from sludge to reduce its volume and weight, facilitating disposal, reuse, or energy recovery.

Efficiency in dewatering directly affects operational cost, energy usage, and environmental compliance.

Moisture Content Importance

Reducing moisture content lowers transportation weight and disposal costs.

Drier sludge improves downstream processes such as incineration, composting, or anaerobic digestion.

Sludge Characteristics

Sludge properties—solids concentration, particle size, organic content, and viscosity—dictate suitable dewatering technologies.

Facilities must assess these characteristics for optimal technology selection.

Benefits of Dewatering Sludge

- Cost Reduction: Less water reduces hauling and landfill fees.

- Volume Reduction: Frees storage space and facilitates handling.

- Operational Efficiency: Prepares sludge for energy recovery or recycling.

Key Dewatering Sludge Technologies

Centrifuge Technology

Centrifuges separate water from solids via high-speed rotation, generating high centrifugal force.

They are suitable for facilities with variable sludge types and high throughput.

Advantages

- High dewatering efficiency across diverse sludge types.

- Compact design suitable for limited spaces.

- Continuous operation with automated controls.

Limitations

- Higher capital and operational costs compared to simpler systems.

- Requires trained operators and regular maintenance.

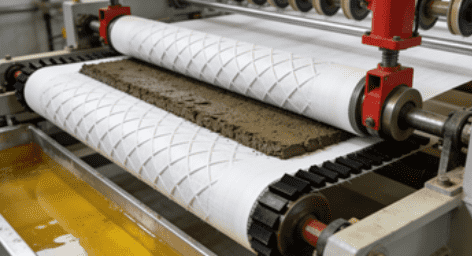

Belt Filter Press

Belt presses use two moving belts to squeeze water from sludge.

They are common in municipal wastewater treatment plants.

Advantages

- Energy-efficient for large volumes.

- Stable operation with moderate solids content.

- Can be integrated into existing treatment processes.

Limitations

- Larger footprint required.

- Reduced efficiency with sticky or high-organic sludge.

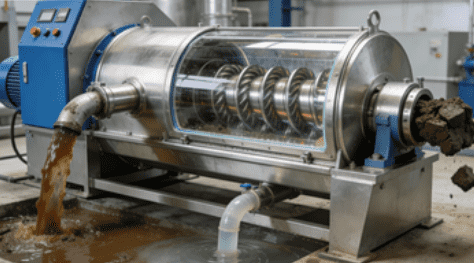

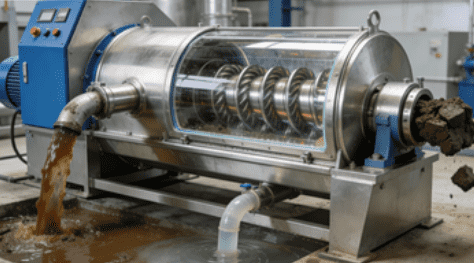

Screw Press Technology

Screw presses mechanically compress sludge via a rotating screw and pressure zones.

Widely applied in industrial and food processing facilities.

Advantages

- Simple operation, low maintenance.

- Cost-effective for medium-scale operations.

Limitations

- Limited performance with very fine sludge.

- Dewatering efficiency lower than centrifuges for some high-solids sludges.

Filter Press

Filter presses apply pressure through filter cloths to separate solids from water.

Common in chemical, mining, and food processing industries.

Advantages

- Produces dry sludge with high solids content.

- Very effective for chemically conditioned or industrial sludges.

Limitations

- Batch operation can limit throughput.

- Requires chemical conditioning for optimal results.

Comparative Analysis of Dewatering Sludge Technologies

Mechanical vs. Chemical Dewatering

- Mechanical: Uses pressure or centrifugal force; low chemical consumption; reliable for municipal sludge.

- Chemical: Uses flocculants/coagulants to enhance solids separation; better for sticky or fine sludge; increases chemical cost.

Thermal vs. Mechanical Dewatering

- Thermal: Evaporates water; achieves very low moisture content; high energy use.

- Mechanical: Uses centrifuges or presses; lower energy cost but may leave higher residual moisture.

Cost vs. Efficiency Trade-Off

Selecting technology requires balancing capital cost, operational expense, throughput, and target dryness.

Lifecycle analysis helps choose the optimal solution.

Industry Data and Trends

Global Market for Dewatering Technologies

According to the Global Water Intelligence report, the industrial sludge dewatering market is expected to grow at 6–8% CAGR from 2023 to 2030.

Increasing regulatory pressures and rising disposal costs drive adoption.

Municipal Adoption

The US EPA reports that municipal facilities achieve 50–70% volume reduction with mechanical dewatering, saving millions annually in hauling and landfill costs.

Industrial Adoption

Industrial sectors such as food, pulp & paper, and chemical processing increasingly implement centrifuges and screw presses to meet strict environmental compliance standards.

Expert Opinions

Industry Leaders on Dewatering

- Dr. Mark van Loosdrecht (TU Delft, Wastewater Specialist): “Optimizing sludge dewatering is not just operational; it is a critical step toward energy recovery and circular water management.”

- EPA Guidance: Facilities that reduce sludge moisture by 10% can cut disposal costs by 20–30%, highlighting the economic significance.

Analyst Viewpoint

Gartner and Deloitte logistics reports identify sludge dewatering as a high-ROI investment for utilities and industrial plants.

Proper technology selection aligns operational efficiency with environmental compliance.

Applications Across Industries

Municipal Wastewater

Centrifuges and belt presses handle large volumes efficiently; typical plants achieve 60%–70% water reduction.

Industrial Wastewater

Screw and filter presses handle high-strength sludges from food, chemical, or pulp industries.

Agriculture and Biogas

Dewatered sludge can be composted or used for anaerobic digestion to produce biogas, reducing waste and generating renewable energy.

Economic Analysis and ROI

Cost Structure

- CapEx: Equipment purchase, installation, and civil works.

- OpEx: Energy, maintenance, chemical dosing, labor.

- Disposal Savings: Reduced hauling and landfill costs.

ROI Examples

- Municipal plants with centrifuges report payback within 3–5 years.

- Industrial facilities adopting screw presses see improved throughput and energy recovery, often justifying investment in 2–4 years.

Future Trends in Dewatering Sludge

AI-Driven Optimization

Emerging systems use AI to optimize feed rates, pressure, and flocculant dosing in real time, improving efficiency and reducing costs.

Energy-Efficient Designs

Next-generation centrifuges and presses reduce electricity use by 20–30% compared to conventional units.

Circular Economy Integration

Dewatered sludge increasingly serves as a raw material for biogas, compost, or fertilizer, supporting sustainable resource recovery.

Smart Monitoring

IoT sensors allow real-time monitoring of moisture content, throughput, and equipment health, enabling predictive maintenance and operational reliability.

Conclusion

Optimizing dewatering sludge is essential for cost-effective, environmentally compliant, and energy-efficient wastewater and industrial operations.

By understanding the technologies—centrifuge, belt press, screw press, and filter press—analyzing sludge characteristics, and considering lifecycle costs, facilities can choose the best solution for their needs.

Incorporating chemical conditioning, automation, and AI-driven monitoring ensures higher performance and prepares facilities for future sustainability initiatives. Dewatering is not just waste management—it is a critical step in resource recovery, circular economy practices, and operational efficiency.

FAQ

“Which dewatering sludge technology is best for municipal wastewater?”

Centrifuges and belt presses dominate municipal applications due to reliability, continuous operation, and moderate capital costs.

“Can chemical flocculants improve performance?”

Yes, especially for fine or sticky sludge. Flocculation enhances solids capture, reducing residual moisture.

“How much volume reduction is typical?”

Mechanical dewatering usually reduces sludge volume by 50–80%, depending on sludge type and method.

“Do dewatering systems require skilled operators?”

Some systems, like centrifuges, require trained staff; screw presses and filter presses are simpler but still need basic operational oversight.

“Is energy recovery possible from dewatered sludge?”

Yes, lower moisture content enhances combustion efficiency or biogas production.