Table of Contents

Effective dewatering sludge solutions play a critical role in modern wastewater treatment. Whether in municipal facilities or industrial plants, reducing sludge volume and moisture content is essential for lowering disposal costs, improving operational efficiency, and meeting environmental regulations.

As an experienced manufacturer of sludge dewatering equipment, we provide reliable and customized dewatering sludge systems designed to handle different sludge characteristics and application requirements.

What Is Dewatering Sludge and Why It Matters

Dewatering sludge refers to the process of removing water from sludge generated during wastewater treatment. Sludge typically contains a high percentage of water, which increases transportation, handling, and disposal costs if not properly treated.

By applying effective dewatering sludge processes, wastewater treatment plants can significantly reduce sludge volume, improve handling efficiency, and minimize environmental impact. Without proper dewatering, sludge disposal becomes costly, inefficient, and difficult to manage.

How the Dewatering Sludge Process Works

The treatment process usually begins with sludge conditioning, where polymers or other agents are added to improve solid-liquid separation. Proper conditioning allows fine particles to form stable flocs, which enhances mechanical separation efficiency.

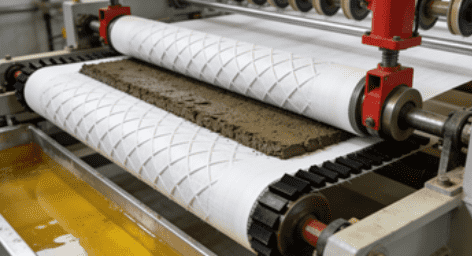

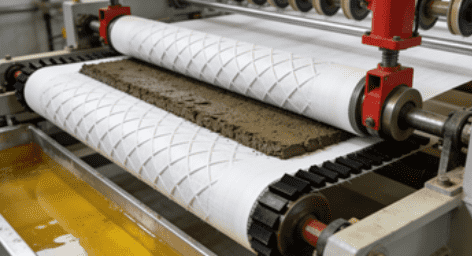

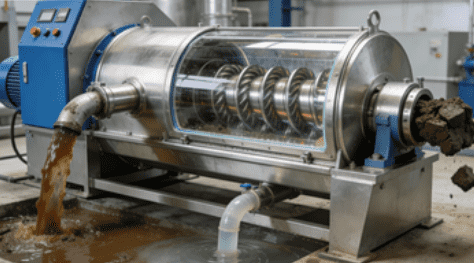

Once conditioned, sludge passes through mechanical equipment that applies pressure or shear force to remove free water. The result is a semi-solid cake with reduced moisture content, suitable for transport, storage, or further treatment.

Common Dewatering Sludge Methods and Technologies

Several mechanical technologies are widely used in wastewater treatment, each offering distinct advantages depending on the application.

Comparison of Common Sludge Dewatering Equipment

| Equipment Type | Main Advantages | Typical Applications |

|---|---|---|

| Belt Press | Continuous operation, simple maintenance | Municipal and general industrial use |

| Screw Press | Compact structure, low energy demand | Industrial and oily sludge |

| Filter Press | High solids content, stable cake | Chemical, mining, special sludge |

| Centrifuge | High throughput, small footprint | Large-scale treatment plants |

Selecting the most suitable solution depends on sludge properties, available space, and operating requirements.

Key Factors Affecting Dewatering Performance

System performance is influenced by several variables. Sludge composition, particle size, and organic content directly affect separation efficiency. Incorrect polymer selection or dosing often leads to unstable operation or increased operating costs.

Equipment design also plays a critical role. Parameters such as pressure, rotation speed, and filtration area must be matched to the specific sludge conditions to achieve consistent results.

Applications Across Industrial and Municipal Sectors

Mechanical dewatering systems are widely applied in municipal wastewater facilities to reduce disposal volume and meet regulatory requirements.

In industrial environments, these systems are commonly used in food and beverage processing, chemical manufacturing, pharmaceuticals, pulp and paper, mining, and metal processing. Each application produces sludge with different characteristics, making system customization essential.

How to Choose the Right Equipment for Your Facility

Choosing the right solution starts with understanding sludge properties and daily treatment capacity. Target cake dryness, footprint limitations, and automation level should also be considered during the planning stage.

Working directly with a manufacturer allows for proper system sizing, optimized configuration, and long-term operational reliability. A well-matched system not only improves performance but also reduces maintenance and operating costs.

Cost and Efficiency Benefits of Mechanical Sludge Treatment

Effective sludge treatment significantly reduces transportation and disposal expenses by minimizing waste volume. Optimized systems also help control energy consumption and chemical usage, contributing to lower overall operating costs.

From an investment perspective, reliable mechanical solutions offer long service life and stable operation, delivering strong returns for wastewater treatment facilities.

Common Operational Challenges and Practical Solutions

Issues such as low solids content, excessive chemical usage, or frequent clogging are often linked to improper system selection or inadequate process control.

These challenges can usually be resolved through equipment optimization, process adjustment, or system redesign. Manufacturer-supported engineering services are especially valuable in achieving stable and consistent operation.

Customized Solutions from a Professional Manufacturer

As a professional equipment manufacturer, we provide tailored solutions based on specific sludge conditions and project requirements. Our scope includes system design, equipment fabrication, testing, and technical support.

By focusing on durability, efficiency, and ease of maintenance, our systems help customers achieve reliable performance and long-term operational stability.

Environmental Compliance and Sustainable Sludge Management

Efficient mechanical treatment supports compliance with environmental regulations by reducing waste volume and improving disposal safety. It also plays an important role in sustainable wastewater management by lowering the environmental footprint of sludge handling.

Conclusion

Effective sludge dewatering is a critical component of modern wastewater treatment strategies. By reducing moisture content and waste volume, treatment facilities can lower operating costs, improve efficiency, and meet environmental compliance requirements.

Partnering with an experienced manufacturer ensures that the selected solution is properly engineered, customized to real operating conditions, and designed for long-term performance. A well-designed system is the foundation for reliable operation and sustainable wastewater management.

Frequently Asked Questions

What is sludge dewatering used for?

Sludge dewatering is used to reduce the moisture content of sludge generated during wastewater treatment. By removing excess water, the process lowers transportation and disposal costs while improving handling efficiency.

Which industries commonly use sludge dewatering systems?

Sludge dewatering systems are widely used in municipal wastewater treatment plants as well as industrial sectors such as food and beverage, chemical processing, pharmaceuticals, pulp and paper, and mining.

How do I choose the right sludge dewatering equipment?

The right equipment depends on sludge characteristics, treatment capacity, required cake dryness, available space, and operating cost considerations. Working with an experienced manufacturer helps ensure proper system selection and long-term reliability.

What affects the performance of a sludge dewatering process?

Performance is influenced by sludge composition, polymer selection, equipment design, and operating parameters. Proper system configuration and process optimization are essential for achieving stable and efficient results.

Can sludge dewatering systems be customized?

Yes. Sludge dewatering systems can be customized to match specific sludge types and project requirements. Customized solutions often deliver better performance, lower operating costs, and more reliable long-term operation.

Need Help Choosing the Right Sludge Dewatering Solution?

If you’re unsure which sludge dewatering system is best for your wastewater treatment process, our experts are here to help. Contact us today for a personalized consultation, and get a solution designed to reduce sludge volume, lower operating costs, and deliver reliable long-term performance.

Don’t let inefficient sludge handling increase your expenses—get in touch now to discuss a customized dewatering solution for your facility.