Table of Contents

Choosing the right grease trap company is a critical decision for restaurants, commercial kitchens, and food service facilities. A reliable grease trap system not only prevents plumbing issues but also ensures compliance with environmental and local regulations. As a professional grease trap manufacturing company, we help commercial buyers understand how grease traps work, how to select the right system, and why working directly with a manufacturer offers long-term advantages.

This guide is designed to help you make an informed decision when selecting a grease trap company for your business.

What Does a Grease Trap Company Do?

A grease trap company typically provides grease management solutions for commercial and industrial applications. These solutions may include product manufacturing, system design, technical support, and after-sales services.

Manufacturing vs Supplying Grease Traps

Not all grease trap companies operate the same way. Some companies act only as suppliers or distributors, while others are full-scale manufacturers. A manufacturing grease trap company designs and produces grease traps in-house, allowing for better quality control, customization, and technical support.

Products and Services Offered by a Grease Trap Company

A professional grease trap company may offer:

- Commercial grease traps

- Grease interceptors for large-capacity applications

- Custom-designed grease management systems

- Technical documentation and installation guidance

How Grease Traps Work in Commercial Kitchens

Grease traps are designed to separate fats, oils, and grease (FOG) from wastewater before it enters the drainage system.

Basic Working Principle of Grease Traps

As wastewater flows through the grease trap, heavier solids sink to the bottom while grease and oils rise to the surface. Clean water exits the system, while grease is retained for periodic removal.

Why Proper Grease Management Is Critical for Businesses

Effective grease management helps:

- Prevent pipe blockages and backups

- Reduce maintenance and repair costs

- Maintain compliance with local plumbing codes

- Protect municipal sewer systems

Types of Grease Traps Manufactured for Commercial Use

Different applications require different grease trap designs. As a manufacturer, we produce multiple grease trap types to suit various operational needs.

Passive Grease Traps

Passive grease traps are commonly used in small to medium-sized kitchens. They rely on gravity separation and are cost-effective for restaurants with moderate grease output.

Automatic Grease Removal Units (AGRU)

AGRUs automatically remove grease from the system, reducing manual cleaning frequency and improving operational efficiency.

Large-Capacity Grease Interceptors

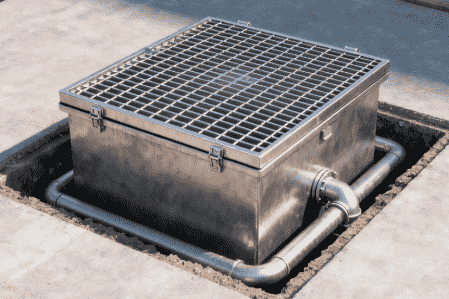

Grease interceptors are designed for high-volume operations such as hotels, food processing plants, and industrial kitchens.

Grease Trap Applications Across Different Industries

Grease trap systems are essential in many commercial and institutional environments.

Restaurants and Commercial Kitchens

Restaurants rely on grease traps to meet health and plumbing regulations while maintaining smooth kitchen operations.

Hotels and Resorts

Large food service operations require durable, high-capacity grease trap systems that can handle continuous use.

Food Processing Plants

Industrial food facilities often need custom grease interceptors designed for high flow rates and strict compliance standards.

Schools, Hospitals, and Institutions

Public facilities require reliable grease management solutions to ensure hygiene, safety, and regulatory compliance.

Key Factors to Consider When Choosing a Grease Trap Company

Selecting the right grease trap company involves more than just comparing prices.

Manufacturing Experience and Technical Expertise

A grease trap manufacturing company with proven experience can provide accurate sizing, system recommendations, and long-term technical support.

Product Quality and Material Options

Material selection impacts durability and performance. Stainless steel grease traps are known for corrosion resistance and long service life, while plastic models may suit lighter applications.

Compliance with Local and International Standards

Ensure the grease trap company understands relevant standards and regulations in your target market.

Manufacturer vs Service-Based Grease Trap Company

Working directly with a manufacturer offers several advantages compared to service-only providers.

| Comparison Factor | Manufacturer | Service-Based Company |

|---|---|---|

| Product Customization | High | Limited |

| Quality Control | In-house | Outsourced |

| Cost Efficiency | Better for bulk orders | Higher long-term cost |

| Technical Support | Direct from engineers | General support |

| Lead Time | Shorter for custom orders | Depends on suppliers |

Custom Grease Trap Solutions from a Manufacturing Company

As a professional grease trap company, we specialize in custom solutions for commercial buyers.

Sizing and Capacity Calculation Support

Proper sizing ensures optimal performance and compliance. Our engineering team assists with flow rate and capacity calculations.

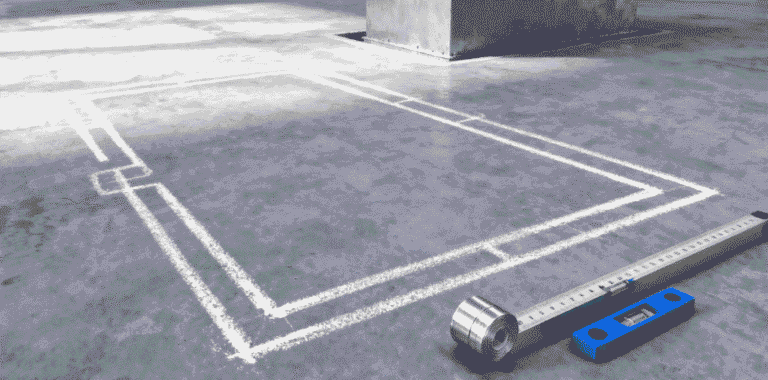

Custom Design for Unique Kitchen Layouts

We design grease traps to fit specific installation spaces and operational requirements.

OEM and Wholesale Options

For distributors, contractors, and large projects, we offer OEM manufacturing and wholesale supply options.

Installation, Maintenance, and Support from a Professional Grease Trap Company

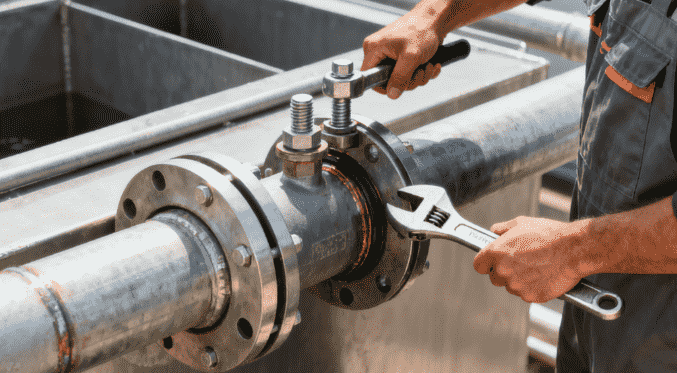

A high-quality grease trap system requires proper installation and ongoing maintenance.

Installation Guidance and Technical Documentation

We provide detailed installation manuals, drawings, and technical specifications to support contractors and project managers.

Maintenance Recommendations for Long-Term Performance

Routine cleaning and inspection extend service life and prevent system failure.

After-Sales Support and Spare Parts Availability

Reliable after-sales support ensures your grease trap system continues to perform efficiently.

Why Choose Our Grease Trap Company as Your Manufacturing Partner

As an experienced grease trap manufacturing company, we focus on quality, customization, and long-term partnerships.

- In-house manufacturing and strict quality control

- Custom designs tailored to commercial applications

- Competitive pricing for bulk and wholesale orders

- Global supply capability and professional support

Frequently Asked Questions About Grease Trap Companies

How do I choose the right grease trap size?

Grease trap sizing depends on kitchen flow rate, fixture count, and grease output. A manufacturer can provide accurate calculations.

How often should grease traps be cleaned?

Cleaning frequency varies by usage but is typically required every 1–3 months for commercial kitchens.

Are custom grease traps more expensive?

Custom solutions may have a higher upfront cost but often reduce long-term maintenance and operational issues.

What certifications should a grease trap manufacturer have?

Look for compliance with relevant plumbing, environmental, and quality standards applicable to your market.

Conclusion

Choosing the right grease trap company is essential for maintaining efficient operations, meeting regulatory requirements, and reducing long-term costs. Working directly with a professional grease trap manufacturing company gives commercial buyers access to high-quality products, custom solutions, and reliable technical support. Whether you operate a restaurant, hotel, or food processing facility, partnering with an experienced manufacturer ensures your grease trap system is built for performance, durability, and compliance.

Need Help Choosing the Right Grease Trap Company?

If you’re unsure which grease trap solution is best for your commercial kitchen or facility, our manufacturing experts are here to help. Contact us today for a personalized consultation and get a high-quality, compliant grease trap designed for your specific needs. Don’t wait until plumbing issues or compliance problems arise—get in touch now and ensure your grease management system performs reliably for the long term.