Table of Contents

Introduction

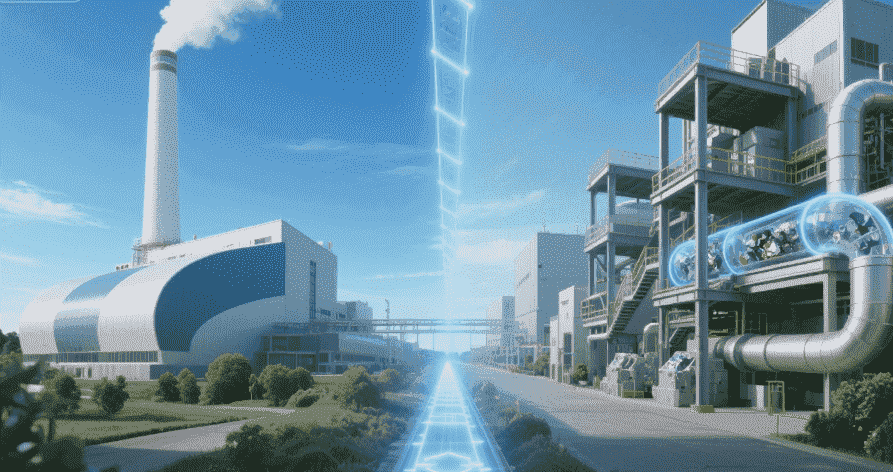

As waste management continues to evolve, garbage incinerators are playing an increasingly crucial role in reducing landfill use, generating energy, and promoting environmental sustainability. The efficiency of a garbage incinerator is paramount, not only to reduce operational costs but also to minimize harmful emissions and maximize energy recovery. With new advancements in technology, modern garbage incinerators are becoming more energy-efficient, environmentally friendly, and cost-effective. In this blog, we will explore the latest technological innovations in garbage incineration, helping B2B buyers understand how these innovations can improve incinerator performance and contribute to sustainable waste management.

What is a Garbage Incinerator?

A garbage incinerator is a specially designed facility that burns waste materials at extremely high temperatures (often between 800°C to 1200°C), converting them into gases, ash, and heat energy. The primary goal is to significantly reduce the volume of waste, often by up to 90%, which makes waste management and disposal more efficient. This method helps minimize the need for landfills, which are becoming increasingly scarce and environmentally challenging to manage.

Garbage incinerators are widely used for various types of waste, including municipal solid waste, hazardous waste, and medical waste. In urban areas, where waste generation is at an all-time high, incineration serves as an essential method of waste disposal.

How Garbage Incinerators Help with Waste Management

The burning process of garbage transforms bulky waste into small amounts of inert ash, reducing its physical volume. Not only does this help clear up space in landfills, but it also reduces the environmental impact caused by waste accumulation. In fact, a garbage incinerator can reduce waste volume by up to 90%, making it a highly efficient solution for large-scale waste management.

A Green Twist: Energy Recovery

One of the most intriguing benefits of modern garbage incinerators is their ability to recover energy from the burning process, turning waste into electricity or district heating. This is known as waste-to-energy (WTE). By capturing the heat generated during combustion, the energy can be used to produce electricity for local grids or provide heating for nearby homes and businesses, making the entire process both economically and environmentally beneficial.

In fact, countries like Sweden and Japan have mastered the art of waste-to-energy and even import waste from other countries to fuel their incinerators and generate power. Sweden’s waste-to-energy plants are so efficient that they supply power to over 900,000 homes, reducing the need for fossil fuels.

Emission Control Technology: Keeping it Clean

Modern garbage incinerators are equipped with cutting-edge emission control systems designed to minimize harmful gases and pollutants released into the atmosphere. Some of the most common pollutants include carbon dioxide (CO2), nitrogen oxides (NOx), and dioxins, all of which are regulated by stringent environmental standards. Incinerators use technologies like selective catalytic reduction (SCR) and flue-gas desulfurization (FGD) to filter out these harmful substances and ensure they meet government regulations.

Additionally, baghouse filters are used to capture fine particulates, ensuring that only clean gases are released into the air.

Fun Fact: Burning Trash to Heat Homes

Did you know that some cities are using the heat generated from burning garbage to warm entire neighborhoods? In places like Copenhagen, Denmark, waste-to-energy plants not only process garbage but also supply district heating to over 100,000 homes in the city. By making use of this heat, cities significantly reduce their reliance on traditional power sources and further lower their carbon footprint.

Key Takeaways:

- Volume Reduction: Incinerators can reduce waste volume by up to 90%, easing landfill pressure.

- Energy Recovery: Modern incinerators capture heat and convert it into electricity or district heating, providing a valuable energy source.

- Emission Control: Advanced technology ensures that harmful emissions are minimized, meeting strict environmental standards.

- Global Innovation: Countries like Sweden and Japan lead the world in efficiently converting waste into energy.

How Does a Garbage Incinerator Work?

A typical garbage incinerator follows a series of stages in its operation:

- Waste Collection and Sorting: The waste is collected and sorted to remove non-combustible materials like metals, glass, and hazardous substances. Sorting helps to ensure that only burnable materials are sent to the incinerator.

- Pre-Treatment: In some cases, the waste undergoes pre-treatment, such as shredding, to make it more suitable for combustion. This also helps to improve the efficiency of the incineration process.

- Combustion: The sorted waste is fed into a combustion chamber, where it is burned at high temperatures, typically ranging from 800°C to 1,200°C. The heat breaks down the waste into gases and ash. Modern incinerators are designed to optimize the combustion process, ensuring that it is as efficient as possible.

- Emission Control: The gases produced during combustion are filtered to remove harmful pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), and particulate matter. This is achieved through advanced air pollution control technologies like selective catalytic reduction (SCR) and fabric filters.

- Energy Recovery: The heat generated during combustion can be used to produce electricity or provide district heating. This makes garbage incineration a valuable tool for energy recovery, contributing to a more sustainable energy system.

- Ash Disposal: The remaining ash is collected and either disposed of in landfills or processed further for reuse in construction materials, depending on the composition of the ash.

Simple Case Study: A City’s Waste Management Solution

Imagine a city with a population of over 500,000 people, generating thousands of tons of waste per day. Historically, the city would rely on large landfills to manage the waste, but as the landfill space began to fill up, the city faced challenges in managing its waste in an environmentally responsible manner.

The city decided to build a state-of-the-art garbage incinerator, which could process up to 2,000 tons of waste per day. Not only did this solution reduce the waste volume by 90%, but it also provided the city with enough electricity to power several thousand homes. In addition to the energy recovery, the incinerator was equipped with advanced pollution control systems to minimize harmful emissions, ensuring that the city met environmental standards.

This solution not only helped the city effectively manage its waste, but it also contributed to its energy production, reducing the need for additional power plants and lowering overall carbon emissions.

Why Garbage Incinerators Are Essential for Waste Management

Garbage incinerators offer several significant benefits for waste management, especially as cities and industries face increasing pressure to reduce landfill use and minimize environmental impact. Below are some of the key advantages:

1. Reduction of Landfill Use

Incineration significantly reduces the volume of waste that needs to be disposed of in landfills. A single ton of waste can be reduced to just a few hundred kilograms of ash, helping alleviate the burden on overfilled landfills.

2. Energy Generation

Garbage incinerators can generate electricity or provide district heating by recovering the heat from combustion. This waste-to-energy capability not only makes incinerators more environmentally friendly but also contributes to energy security by producing renewable energy.

3. Environmental Benefits

Modern garbage incinerators are designed to minimize harmful emissions. The latest emission control technologies ensure that pollutants like dioxins, furans, and particulates are effectively removed, making incineration a cleaner option compared to landfilling.

4. Cost Efficiency

While the initial investment in a garbage incinerator can be significant, the operational costs are often lower than other waste disposal methods. The energy recovery aspect of incinerators can also help offset these costs, making them a financially viable solution in the long term.

Key Technological Innovations in Garbage Incinerators

The efficiency of garbage incinerators has dramatically improved over the years due to technological advancements. Some of the latest innovations that have transformed the industry include:

1. Advanced Combustion Technology

The development of high-efficiency combustion systems has improved the performance of garbage incinerators. These systems maximize the energy extracted from waste while minimizing the production of harmful pollutants. By optimizing air-fuel ratios and using multi-stage combustion chambers, modern incinerators can burn waste more efficiently, reducing fuel consumption and emissions.

2. Energy Recovery Systems

Energy recovery systems have become a standard feature in modern incinerators. These systems capture the heat generated during combustion and convert it into usable energy, such as electricity or steam. This significantly increases the overall efficiency of the incinerator, making it a more sustainable and cost-effective option for waste disposal.

3. Emission Control Technologies

The latest emission control technologies, including selective catalytic reduction (SCR) and flue gas desulfurization (FGD), have made modern garbage incinerators much cleaner. These technologies remove harmful gases like nitrogen oxides (NOx) and sulfur dioxide (SO2) from the exhaust gases, reducing the environmental impact of incineration.

4. Automated Monitoring Systems

The integration of IoT (Internet of Things) technologies in garbage incinerators allows for real-time monitoring and control of incinerator operations. These automated systems provide data on temperature, pressure, emissions, and energy production, helping operators optimize performance and detect potential issues before they become problems.

5. Low-Emission Designs

New incinerators are designed to produce fewer emissions while maintaining high combustion efficiency. Innovations in air flow control, combustion chamber design, and post-combustion treatment ensure that the environmental impact of incinerators is minimized.

Table: Comparison of Traditional vs. Modern Garbage Incinerators

| Feature | Traditional Incinerators | Modern Incinerators |

|---|---|---|

| Combustion Efficiency | Moderate | High |

| Energy Recovery | Limited | Extensive |

| Emission Control | Basic | Advanced (SCR, FGD) |

| Automation | Manual/Low | High (IoT, AI) |

| Maintenance Requirements | High | Low |

| Environmental Impact | Moderate | Low (Low NOx, SO2) |

| Cost Efficiency | High upfront costs | High ROI, Long-term savings |

| Waste Reduction | Moderate | High |

How to Optimize Garbage Incinerator Efficiency

To make the most of a garbage incinerator, efficiency must be carefully managed. Here are some strategies to optimize the performance of your incinerator:

1. Regular Maintenance

Regular maintenance ensures that the incinerator operates at peak efficiency. This includes inspecting combustion chambers, cleaning emission control systems, and calibrating monitoring equipment.

2. Optimizing Waste Sorting

Proper waste sorting before incineration helps ensure that only combustibles are sent to the incinerator. This minimizes waste composition issues and enhances combustion efficiency.

3. Upgrading to Advanced Technology

Upgrading to the latest combustion and emission control technologies can significantly improve the efficiency and environmental impact of your garbage incinerator.

4. Energy Recovery Integration

Integrating energy recovery systems into your incinerator setup can help you recover heat and generate electricity, making the process more cost-effective and sustainable.

Conclusion

The garbage incinerator technology has come a long way, and with the latest advancements, these systems are now more efficient, environmentally friendly, and cost-effective than ever. By understanding the key features of modern incinerators, including advanced combustion technologies, energy recovery systems, and emission control technologies, B2B buyers can make informed decisions to maximize the efficiency and sustainability of their waste management operations. Investing in a modern garbage incinerator not only helps reduce waste volume but also contributes to energy generation, making it a valuable addition to any waste disposal strategy.

FAQ

How do garbage incinerators reduce waste volume?

Garbage incinerators reduce waste volume by burning the waste at high temperatures, which converts it into ash, gases, and heat. The remaining ash is only a small fraction of the original waste, often reducing volume by up to 90%.

Are modern garbage incinerators environmentally friendly?

Yes, modern garbage incinerators are designed with advanced emission control systems, like SCR and FGD, to reduce pollutants and minimize environmental impact. They also integrate energy recovery systems to produce electricity or heat, making them more sustainable.

What is the role of energy recovery in garbage incineration?

Energy recovery systems capture the heat generated during combustion and convert it into electricity or steam, increasing the efficiency of the incineration process and reducing overall energy consumption.

How does waste sorting improve incinerator efficiency?

Proper waste sorting ensures that only combustible materials are sent to the incinerator, improving combustion efficiency and reducing wear and tear on the incinerator equipment.

What are the benefits of upgrading to modern incinerator technology?

Upgrading to modern incinerator technology improves combustion efficiency, reduces emissions, integrates energy recovery, and lowers