Table of Contents

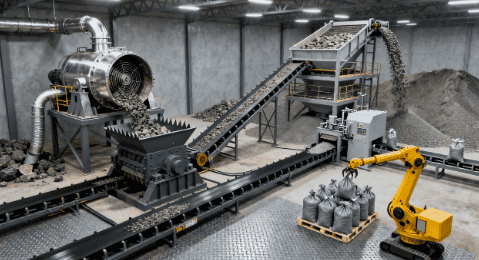

Producing clean, high-quality sand is a key requirement in construction, quarrying, and mining projects. Efficient washing equipment plays an important role in removing clay, dust, and impurities from raw materials, helping producers meet strict quality standards and improve overall product value.

This article explains how sand washing equipment works, the main equipment types, typical applications, cost considerations, and how to select a reliable manufacturer for long-term cooperation.

What Is a Sand Washing Machine?

Sand washing equipment is designed to clean sand and aggregates by separating unwanted materials such as silt, clay, and fine dust through water-based washing and mechanical movement.

Definition and Function of a Sand Washing Machine

The main purpose of this equipment is to improve material quality by washing and dewatering sand, making it suitable for concrete mixing, asphalt production, and other industrial uses.

Why Sand Washing Is Essential for Construction and Mining

Unprocessed sand often contains excessive impurities that can affect strength and durability. Proper washing helps improve gradation, reduce mud content, and ensure compliance with construction standards.

How Does a Sand Washing Machine Work?

The washing process relies on a combination of water flow and mechanical agitation to separate clean sand from impurities.

Sand Washing Process Step by Step

- Raw material is fed into the washing unit

- Water loosens clay and fine particles

- Rotating or spiral motion separates impurities

- Clean sand is discharged for further processing

Key Components of a Sand Washing Machine

- Feeding and discharge systems

- Washing wheel or spiral shaft

- Water spray and drainage system

- Drive and transmission components

Types of Sand Washing Machines

Different washing structures are designed to match various material conditions and production requirements.

Wheel Sand Washing Machine

Wheel-type washers are suitable for materials with relatively low mud content. They feature a simple structure, stable operation, and lower water consumption.

Spiral Sand Washing Machine

Spiral-type washers are more effective for materials with higher clay content. They provide stronger washing action and are commonly used in mining and quarry applications.

Fine Sand Washing and Recycling Machine

This integrated system combines washing, dewatering, and fine sand recovery, helping reduce material loss and improve overall efficiency.

Applications of Sand Washing Machines

Sand washing solutions are widely used across multiple industries and material sources.

- Quarry and Aggregate Processing

- Construction Sand and Concrete Production

- River Sand, Sea Sand, and Crushed Sand

- Mining and Silica Sand Processing

Each application requires a tailored configuration based on raw material properties and finished product standards.

How to Choose the Right Sand Washing Machine for Your Project

Proper equipment selection directly affects production efficiency and operating costs.

Capacity Requirements (TPH)

The required output capacity should match upstream crushing and screening systems to avoid bottlenecks.

Sand Type and Mud Content

Material characteristics determine whether wheel-type, spiral-type, or fine recovery systems are more suitable.

Water Consumption and Environmental Requirements

Modern washing systems often include water recycling options to reduce environmental impact.

Matching with Other Equipment

Washing units are usually integrated with crushers, screens, and dewatering equipment to form a complete processing line.

Sand Washing Machine Price and Cost Factors

Equipment investment varies depending on configuration and performance requirements.

What Affects the Price of a Sand Washing Machine?

- Equipment structure and size

- Processing capacity

- Wear-resistant materials

- Level of automation

- Custom design requirements

Sand Washing Machine Price Range by Capacity

| Capacity (TPH) | Typical Equipment Type | Investment Level |

|---|---|---|

| 30–50 | Wheel-type washer | Low to Medium |

| 50–100 | Spiral washer | Medium |

| 100–200 | Double spiral / fine recovery | Medium to High |

| 200+ | Customized washing solution | High |

Actual cost depends on technical specifications and site conditions.

Why Buy Directly from a Manufacturer

Working directly with an equipment manufacturer offers clear advantages in terms of cost control, customization, and long-term support.

- Factory Pricing and Cost Control

- Customized Solutions and OEM Services

- Quality Control and Certification Standards

- Technical Support and Spare Parts Supply

Sand Washing Machine for Sale – Our Manufacturing Capabilities

As a professional equipment manufacturer, we focus on delivering reliable washing solutions tailored to real project requirements.

Equipment Models and Technical Specifications

Our product range includes wheel-type washers, spiral washers, and complete washing and recycling systems.

Customized Plant Solutions

We provide technical proposals based on capacity, material type, and site layout to ensure efficient operation.

Global Supply Experience

Our equipment has been supplied to customers in quarrying, construction, and mining projects worldwide.

How to Request a Quotation

You can contact our technical team with your project details to receive a detailed solution and competitive factory quotation.

Common Problems in Washing Plants and Practical Solutions

- Excessive Water Consumption

- Fine Material Loss

- Equipment Wear and Maintenance Challenges

- Optimized designs and optional recycling systems help address these issues effectively.

Conclusion

Efficient sand washing equipment plays a crucial role in producing qualified materials for construction, quarrying, and mining applications. Selecting the right configuration and working with a reliable manufacturer helps improve product quality, control operating costs, and ensure long-term stability.

As an experienced manufacturer, we provide customized solutions, factory-direct pricing, and professional technical support. Contact us today to receive a free technical proposal and competitive quotation for your project.

FAQ

What is a sand washing machine used for?

A sand washing machine is used to remove clay, silt, and impurities from raw sand, improving its quality for construction, quarry, and mining applications.

How do I choose the right sand washing machine for my project?

The right choice depends on material type, mud content, required capacity, water conditions, and how the equipment integrates with your existing production line.

What is the typical price range of a sand washing machine?

The price varies based on machine type, capacity, and configuration. Small-capacity units cost less, while large or customized systems require higher investment.

Can a sand washing machine handle high clay or mud content?

Yes. Spiral-type washers and fine sand recovery systems are designed to process materials with high clay and mud content efficiently.

Why should I buy a sand washing machine directly from the manufacturer?

Buying directly from the manufacturer offers factory pricing, customized solutions, better quality control, and reliable after-sales technical support.

Need Help Choosing the Right Sand Washing Machine?

If you’re not sure which sand washing solution is best for your project or material type, our experienced engineers are here to help. As a professional manufacturer, we provide technical guidance, customized equipment solutions, and competitive factory pricing tailored to your production needs.

Contact us today for a personalized consultation and free technical proposal.

Don’t let inefficient washing equipment limit your production—get in touch now and build a reliable, high-performance sand washing system with confidence.