Table of Contents

Efficient sludge handling is a critical part of modern wastewater treatment. As disposal costs continue to rise and environmental regulations become more stringent, both industrial facilities and municipal plants are seeking reliable solutions to reduce sludge volume and improve overall treatment efficiency.

As an experienced manufacturer of sludge dewatering equipment, we design and supply customized solutions that help clients lower operating costs, improve solid–liquid separation performance, and ensure stable long-term operation.

What Is a Sludge Dewatering System?

This type of treatment equipment is designed to remove excess water from sludge generated during wastewater treatment processes. By reducing moisture content, sludge volume is significantly decreased, making transportation, disposal, or further processing more economical.

Such equipment is widely applied in:

- Municipal wastewater treatment plants

- Industrial effluent treatment facilities

- Food, chemical, textile, paper, and mining industries

The primary objective is to convert liquid sludge into a semi-solid cake with lower water content.

How Does a Sludge Dewatering System Work?

The dewatering process generally includes several key stages:

Sludge conditioning – Polymers or chemicals are added to improve floc formation.

Mechanical separation – Pressure, gravity, or centrifugal force is applied to separate water from solids.

Filtrate discharge – Separated liquid is returned to the treatment process.

Sludge cake discharge – Dewatered solids are collected for disposal or reuse.

A properly engineered solution ensures stable performance, low energy consumption, and consistent cake dryness.

Types of Sludge Dewatering Systems We Manufacture

As a professional manufacturer, we provide multiple mechanical dewatering technologies to meet different operational requirements and sludge characteristics.

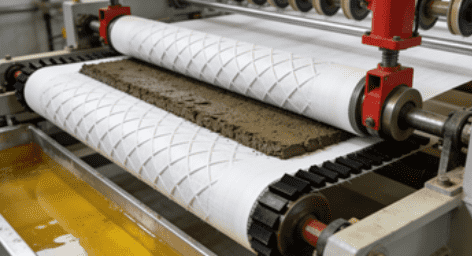

Belt Press Dewatering Equipment

Well suited for municipal plants and large-capacity industrial projects, offering continuous operation and reliable performance.

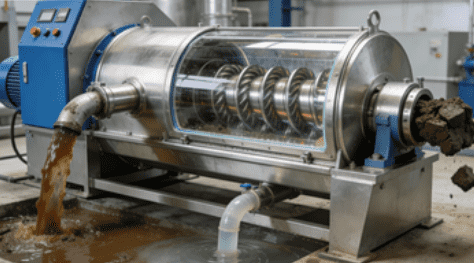

Screw Press Dewatering Equipment

Compact, energy-efficient, and ideal for low-concentration sludge, commonly used in industrial and food-related wastewater treatment.

Centrifugal Dewatering Equipment

High-speed operation with strong separation capability, suitable for complex or difficult sludge types.

How to Choose the Right Type for Your Application

Selection depends on sludge properties, treatment capacity, available space, and long-term operating cost expectations.

Industrial & Municipal Applications of Dewatering Equipment

Our dewatering solutions are widely used across municipal and industrial sectors.

Municipal Wastewater Treatment

Designed for large flow rates, continuous operation, and stable solids discharge.

Industrial Wastewater Treatment

Customized configurations for:

- Food and beverage processing

- Chemical and pharmaceutical industries

- Textile and dyeing plants

- Paper mills

Each application requires specific materials, corrosion resistance, and automation levels.

Key Factors to Consider When Choosing a Dewatering Solution

Before purchasing mechanical dewatering equipment, the following aspects should be carefully evaluated:

Sludge Characteristics and Treatment Capacity

Moisture content, organic composition, and daily sludge volume directly influence equipment selection.

Required Cake Dryness

Different disposal or reuse methods require different levels of moisture reduction.

Operating Cost and Maintenance

An optimal solution balances initial investment with long-term energy use and maintenance needs.

Dewatering Equipment Cost: What Affects the Price?

Pricing varies based on several technical and configuration factors:

| Factor | Influence on Cost |

|---|---|

| Equipment type | Belt press, screw press, or centrifuge |

| Treatment capacity | Larger capacity requires bigger equipment |

| Automation level | Manual or fully automatic operation |

| Construction material | Carbon steel or stainless steel |

| Custom design | Industry-specific requirements |

Choosing the right configuration can significantly reduce total lifecycle costs.

Why Choose Us as Your Dewatering Equipment Manufacturer

We are not only a supplier, but a solution-driven manufacturing partner.

In-House Design and Manufacturing

From engineering design to fabrication and testing, every step is strictly controlled to ensure quality and reliability.

Customized Solutions for Different Industries

Each project is tailored based on site conditions, sludge characteristics, and operational goals.

Global Project Experience

Our equipment has been supplied to international markets and complies with recognized quality and safety standards.

Turnkey Dewatering Solutions for Your Project

We provide complete turnkey services, including:

- Process design and equipment selection

- Manufacturing and factory testing

- Installation and commissioning support

- Operator training and after-sales service

OEM and export services are available for overseas projects.

Common Sludge Dewatering Challenges and Our Solutions

Low Separation Efficiency

Optimized flocculation systems and mechanical design improve solids capture.

High Disposal Costs

Higher cake dryness reduces transportation and landfill expenses.

Operation and Maintenance Issues

User-friendly layouts and durable components ensure reliable daily operation.

FAQ

What is a sludge dewatering system used for?

It is used to remove excess water from sludge generated during wastewater treatment, reducing sludge volume and disposal costs.

How do I choose the right sludge dewatering system for my application?

Selection depends on sludge characteristics, treatment capacity, available space, and required sludge cake dryness.

Which industries commonly use sludge dewatering systems?

They are widely used in municipal wastewater treatment, food processing, chemical, textile, paper, and mining industries.

What factors affect the cost of a sludge dewatering system?

Key factors include equipment type, processing capacity, automation level, construction materials, and customization requirements.

Can a sludge dewatering system be customized for specific projects?

Yes. Manufacturers can design customized solutions based on industry requirements, site conditions, and operational goals.

Conclusion

Choosing the Right Dewatering Solution from a Reliable Manufacturer

Selecting the right dewatering solution plays a vital role in wastewater treatment efficiency and cost control. As an experienced manufacturing partner, we provide reliable, customized, and cost-effective equipment for both industrial and municipal applications.

If you are planning a wastewater treatment project or upgrading existing facilities, contact us today for professional consultation and a tailored solution that meets your technical and budget requirements.

Need Help Choosing the Right Sludge Dewatering System?

If you’re unsure which solution best fits your wastewater treatment needs, our experts are here to help. Contact us today for a personalized consultation and receive a customized dewatering solution designed for efficiency, reliability, and long-term performance. Don’t let sludge handling increase your operating costs—get in touch now and optimize your treatment process with confidence.